|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

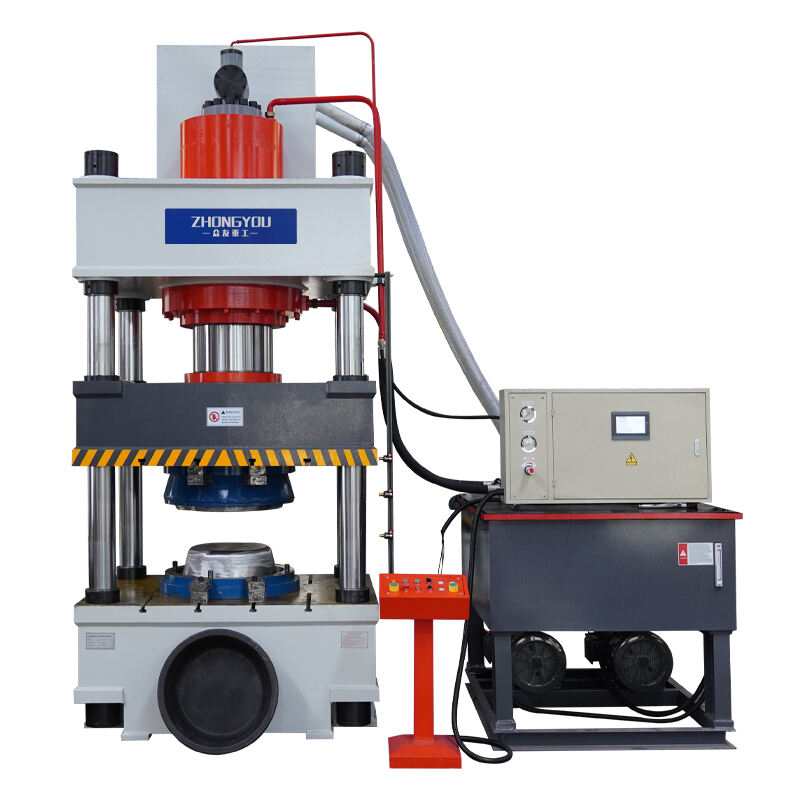

Zhongyou |

|

Model Number: |

YQ32-500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

This is a customized 500-ton composite hot press line for the production of plastic pots, whose core function is to soften plastic raw materials (such as thermoset plastics, engineering plastics) after heating, through high-pressure pressure to make it full of mold cavities, and ultimately cooled and cured to form the required shape of the plastic products.

Plastic product molding

Large plastic tubs: such as laundry tubs for household use and industrial storage tubs, thick-walled and high-strength structures are realized through high-pressure pressing.

Composite material manhole covers: Glass Fiber Reinforced Plastic (GFRP) or BMC material manhole covers, which require 500 tons of pressure to ensure material compactness.

Sanitary ware: such as toilet tanks and wash basins, the molding process can achieve complex curved surfaces and smooth surfaces.

Industrial Material Processing

Resin manhole cover/drainage ditch: High-pressure pressing improves the abrasion and impact resistance of the material.

U-channel/leakage plate: plastic components for agriculture or construction, molding process can mass produce standardized products.

Special material molding

Carbon fiber/quartzite composite material: high pressure is required to ensure that the fiber is fully infiltrated with the matrix material to enhance the mechanical properties of the product.

Strong structural stability

It adopts three-beam and four-column frame structure, which consists of upper beam, slider and working table forming a closed whole through four columns, and is optimized by computer to ensure high rigidity.Four

Efficient and reliable hydraulic system

Integrated cartridge valve technology reduces hydraulic shock and leakage points, and action response speed is increased by more than 30%.Equipped with variable pump oil supply system and high-flow centralized control valve block, it supports two kinds of molding process of fixed-pressure and fixed-range, and the function of pressure maintaining and delaying.The oil cylinder adopts five-cylinder design, and the seal ring has excellent anti-aging performance to ensure stable pressure output without leakage.

Intelligent electrical control

PLC programmable controller is adopted to realize automatic control, supporting three operation modes: adjustment, manual and semi-automatic.Through the operation panel can be accurately set the working pressure of the slider, no-load fast downstream speed (up to 100mm / s) and slow working range (4-10mm / s), to meet the sheet metal stretching, flanging, bending and other complex process requirements.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved