|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ32-500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

500 tons four-column hydraulic press is a general-purpose hydraulic molding equipment, because of its use of four columns as a guiding structure, with good rigidity, high precision, flexible operation and so on, widely used in metal, non-metallic materials, pressing, molding, calibration and It is widely used in metal and non-metal materials pressing, molding, calibrating and assembling processes.

|

YQ32 Technical Parameters |

||||||||

|

|

Unit |

YQ32—63 |

YQ32—100A |

YQ32—100B |

YQ32—200A |

YQ32—200B |

YQ32—315A |

YQ32—315B |

|

Nominal force |

KN |

630 |

1000 |

1000 |

2000 |

2000 |

3150 |

3150 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

700 |

800 |

900 |

900 |

1100 |

1000 |

1250 |

|

Max Stroke of Slider |

mm |

400 |

500 |

600 |

600 |

700 |

600 |

800 |

|

Effective table size |

mm |

610×500 |

630×550 |

750×700 |

800×800 |

1000×1000 |

800×800 |

1260×1160 |

|

Down speed |

mm/s |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Pressing speed |

mm/s |

11~22 |

7~15 |

7~15 |

7~18 |

7~18 |

7~12 |

7~12 |

|

Return speed |

mm/s |

80 |

90 |

90 |

90 |

90 |

90 |

100 |

|

Ejection cylinder force |

KN |

100 |

200 |

200 |

400 |

400 |

630 |

630 |

|

Stroke of ejection cylinder |

mm |

160 |

200 |

200 |

200 |

200 |

300 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

YQ32—400 |

YQ32—500 |

YQ32—630 |

YQ32—800 |

YQ32—1000 |

YQ32—1250 |

YQ32—1600 |

|

Nominal force |

KN |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

16000 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Max Stroke of Slider |

mm |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Effective table size |

mm |

1260×1160 |

1400×1400 |

1500×1500 |

1600×1600 |

1600×1600 |

1600×1600 |

1600×1600 |

|

Down speed |

mm/s |

100 |

150 |

150 |

180 |

180 |

180 |

190 |

|

Pressing speed |

mm/s |

5~11 |

10~18 |

9~18 |

9~18 |

10~18 |

6~15 |

6~14 |

|

Return speed |

mm/s |

100 |

180 |

200 |

180 |

220 |

200 |

220 |

|

Ejection cylinder force |

KN |

630 |

1000 |

1000 |

1000 |

1000 |

1000 |

1600 |

|

Stroke of ejection cylinder |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

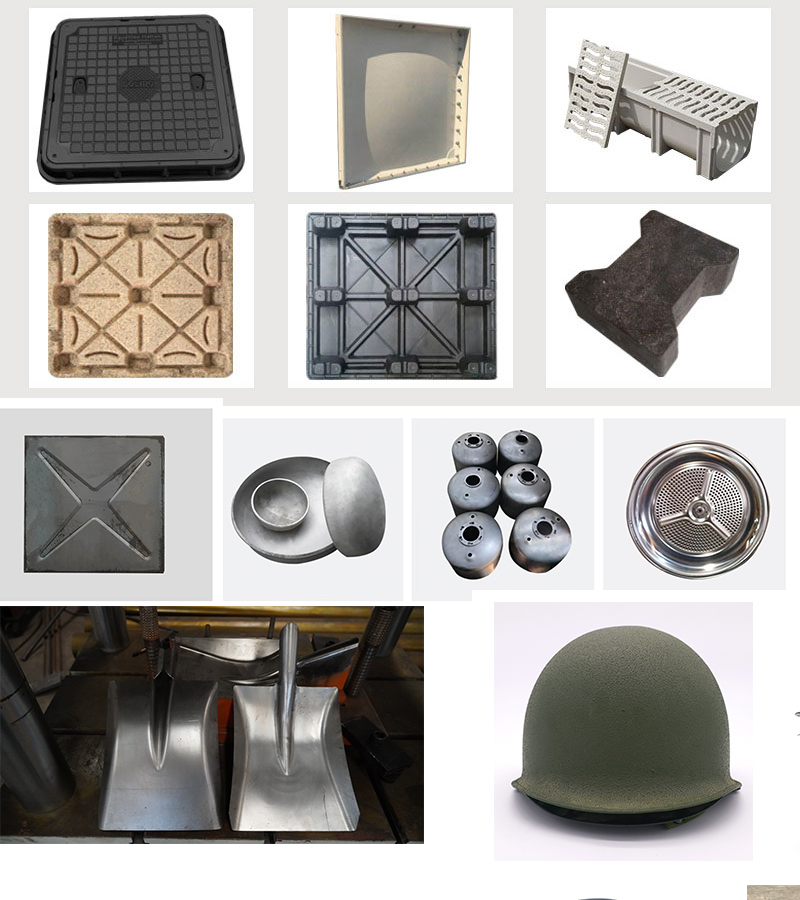

Metal molding

Stamping: drop, bend, and flanging of automotive parts (e.g., brackets, connecting rods, clutch plates), hardware parts (flanges, gaskets, gear blanks).

Drawing: Stainless steel sinks, aluminum radiators, deep cylindrical parts (such as battery shells) deep-drawing molding (need to be equipped with stretching pads to prevent wrinkles).

Alignment: straightening of shafts and plates (e.g. machine tool rails, H-beams for construction).

2. Non-metallic material molding

Plastic molding: hot press molding of PVC plate, PEEK rod; vulcanization molding of rubber products (sealing ring, shock absorbing pad).

Powder metallurgy: pressing of iron-based and copper-based powder products (such as gears and bearings).

Composite materials: molding of fiberglass reinforced plastic (FRP), carbon fiber prepreg (e.g. wind turbine blade parts, sports equipment).

3. Other Processes

Press-fitting: assembly of bearings, gears and shafts with interference fit (e.g. press-in of motor rotors and shafts).

Powder sintering: Pressing-sintering integration of cemented carbide and ceramic products.

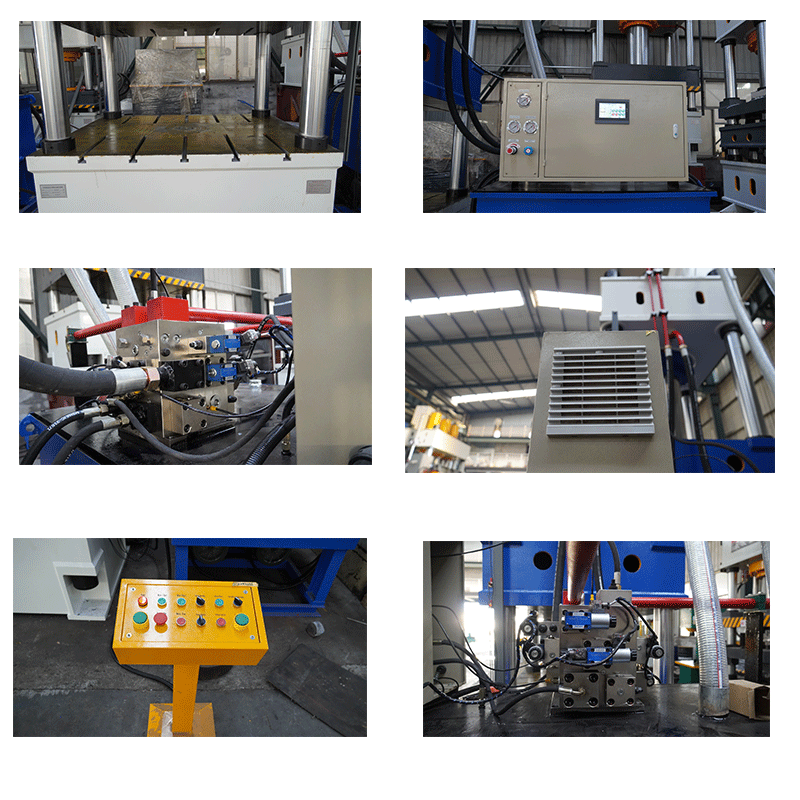

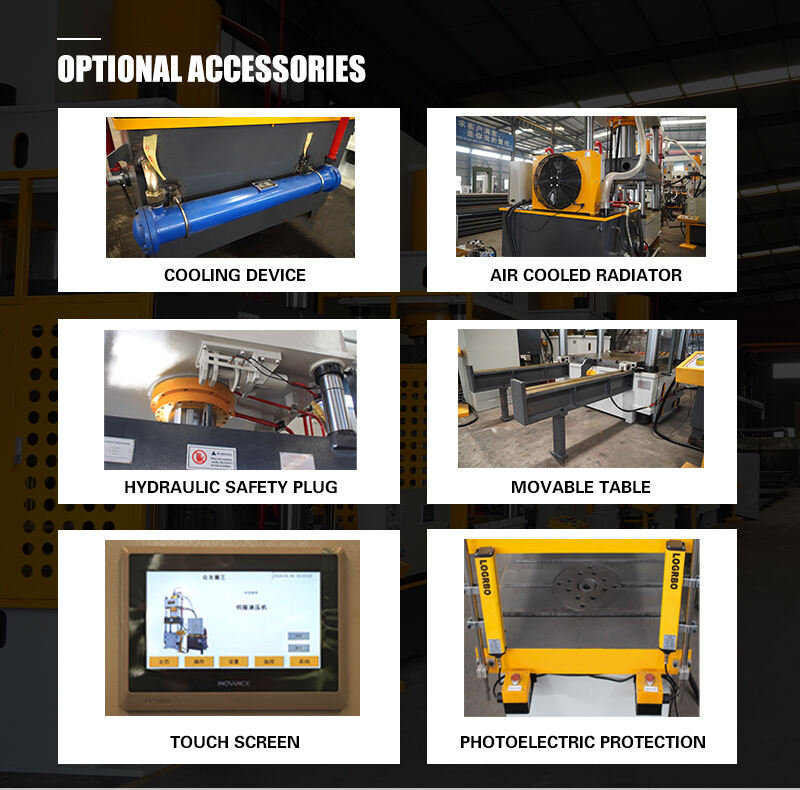

Three-beam and four-column design

Stability and Rigidity: Adopting three-beam structure of upper crossbeam, slider and working table with four column guides to ensure even pressure bearing on the large table surface, and the rigidity of the machine body is increased by more than 30%.

Modular expansion: support the integration of moving table, hydraulic pad and other accessories to meet the needs of multi-process compound processing.

Hydraulic system and control technology

Cartridge Valve Integrated System: Adopting 2-way cartridge valve, action response speed is increased by 40%, and leakage risk is reduced by 50%.

PLC servo control: supports real-time adjustment of parameters such as pressure, stroke, holding time, etc., with process repeatability of ±0.1mm. some models are equipped with a touch screen, which can be used to switch between automatic/manual modes with one key, thus improving operation efficiency by 50%.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved