|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ32-400T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

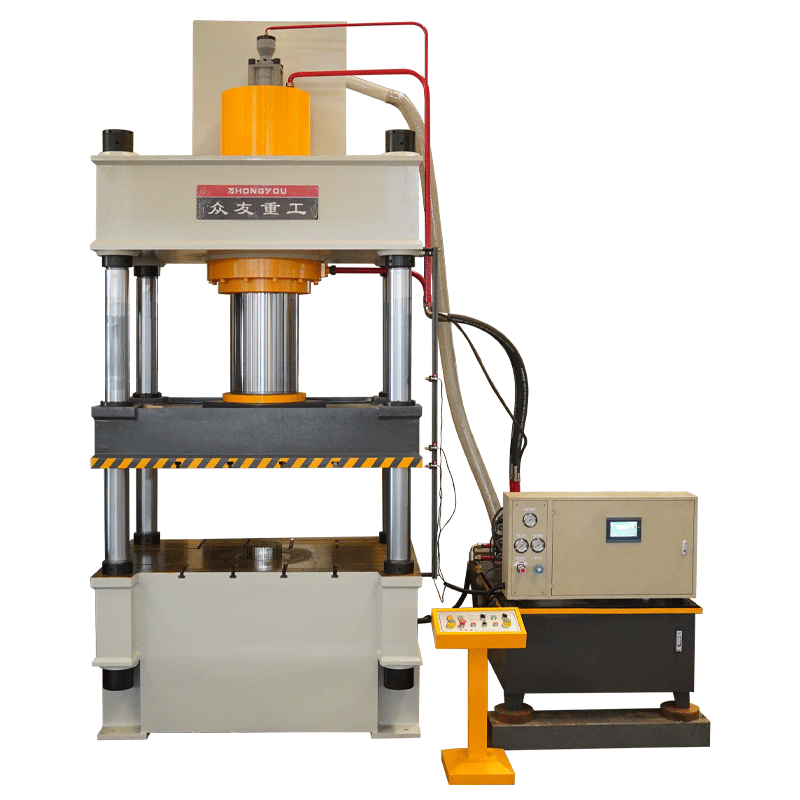

Bulletproof plate forming hydraulic press is specially used for processing metal materials (such as steel plate, aluminum alloy) or composite materials (such as ceramic-based composite materials, ultra-high molecular weight polyethylene UHMWPE and its composite plates) into bulletproof plates with high-strength protective properties of the core equipment.

|

YQ32 Technical Parameters |

||||||||

|

|

Unit |

YQ32—63 |

YQ32—100A |

YQ32—100B |

YQ32—200A |

YQ32—200B |

YQ32—315A |

YQ32—315B |

|

Nominal force |

KN |

630 |

1000 |

1000 |

2000 |

2000 |

3150 |

3150 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

700 |

800 |

900 |

900 |

1100 |

1000 |

1250 |

|

Max Stroke of Slider |

mm |

400 |

500 |

600 |

600 |

700 |

600 |

800 |

|

Effective table size |

mm |

610×500 |

630×550 |

750×700 |

800×800 |

1000×1000 |

800×800 |

1260×1160 |

|

Down speed |

mm/s |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Pressing speed |

mm/s |

11~22 |

7~15 |

7~15 |

7~18 |

7~18 |

7~12 |

7~12 |

|

Return speed |

mm/s |

80 |

90 |

90 |

90 |

90 |

90 |

100 |

|

Ejection cylinder force |

KN |

100 |

200 |

200 |

400 |

400 |

630 |

630 |

|

Stroke of ejection cylinder |

mm |

160 |

200 |

200 |

200 |

200 |

300 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

YQ32—400 |

YQ32—500 |

YQ32—630 |

YQ32—800 |

YQ32—1000 |

YQ32—1250 |

YQ32—1600 |

|

Nominal force |

KN |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

16000 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Max Stroke of Slider |

mm |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Effective table size |

mm |

1260×1160 |

1400×1400 |

1500×1500 |

1600×1600 |

1600×1600 |

1600×1600 |

1600×1600 |

|

Down speed |

mm/s |

100 |

150 |

150 |

180 |

180 |

180 |

190 |

|

Pressing speed |

mm/s |

5~11 |

10~18 |

9~18 |

9~18 |

10~18 |

6~15 |

6~14 |

|

Return speed |

mm/s |

100 |

180 |

200 |

180 |

220 |

200 |

220 |

|

Ejection cylinder force |

KN |

630 |

1000 |

1000 |

1000 |

1000 |

1000 |

1600 |

|

Stroke of ejection cylinder |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

Protective equipment for single soldier

Material combination: ceramic top layer (to blunt projectiles) + PE or aramid fiber back layer (to disperse impact energy).

Fiber Composite Layer: Pre-treated aramid fabrics are laid alternately with polyurea coatings and cured and molded through a hot press tank.

Special material molding

Metal-ceramic composite plate: Hydraulic machine presses B4C or TBC high hardness ceramic block spliced to meet the projectile surface, combined with metal backing plate, to realize the balance of light weight and high protection performance.

Ultra-high-pressure molding: For ultra-high-strength bullet-proof steel plate, rapid hydraulic presses are used to quench the pressure under 200-300 tons of pressure, and the molds are cooled by water to ensure the flatness of the plate.

Bulletproof plate molding hydraulic press is based on Pascal's law, which realizes material pressing by transferring pressure through high-pressure oil.Its core structure includes:

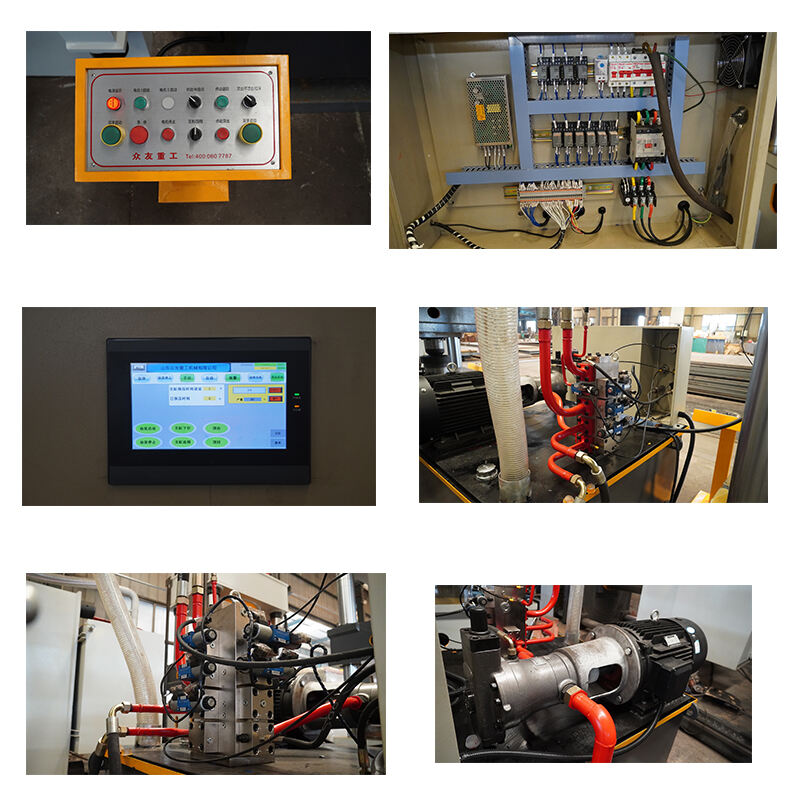

Hydraulic system: it consists of oil pump, hydraulic valve, oil tank and pipeline to provide stable and high pressure oil source.

Actuator: hydraulic cylinder and piston combination, the oil pressure is converted into mechanical force to push the mold closed or open the mold.

Control system: PLC or numerical control system is adopted to realize the precise regulation and control of pressure, speed, holding time and other parameters.

Mold system: special molds are designed according to the characteristics of bulletproof plate materials (such as ceramic, PE, aramid fiber) to ensure molding precision.

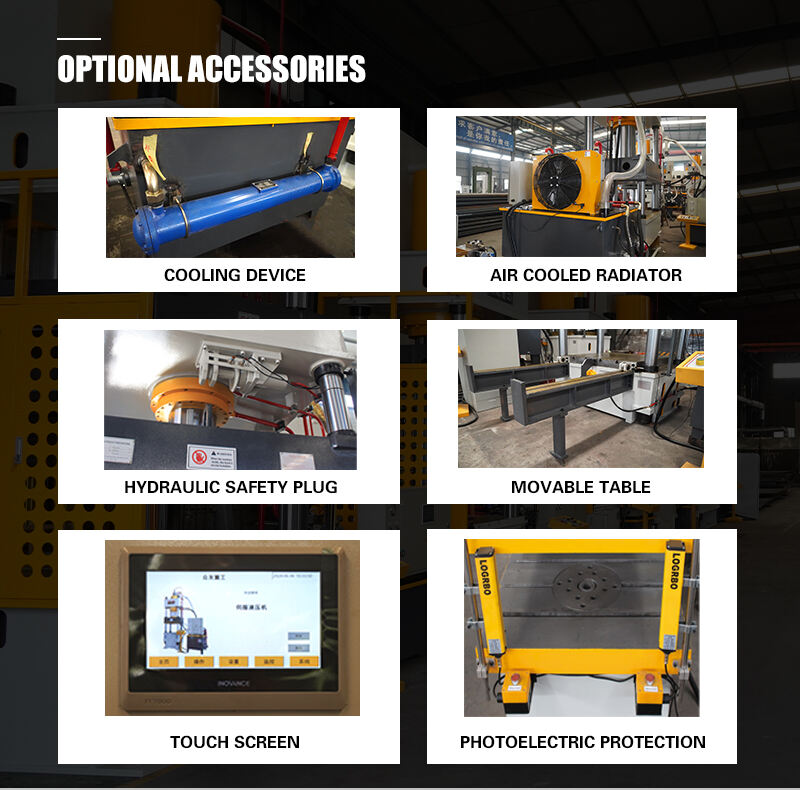

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved