|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YZ79-400T |

|

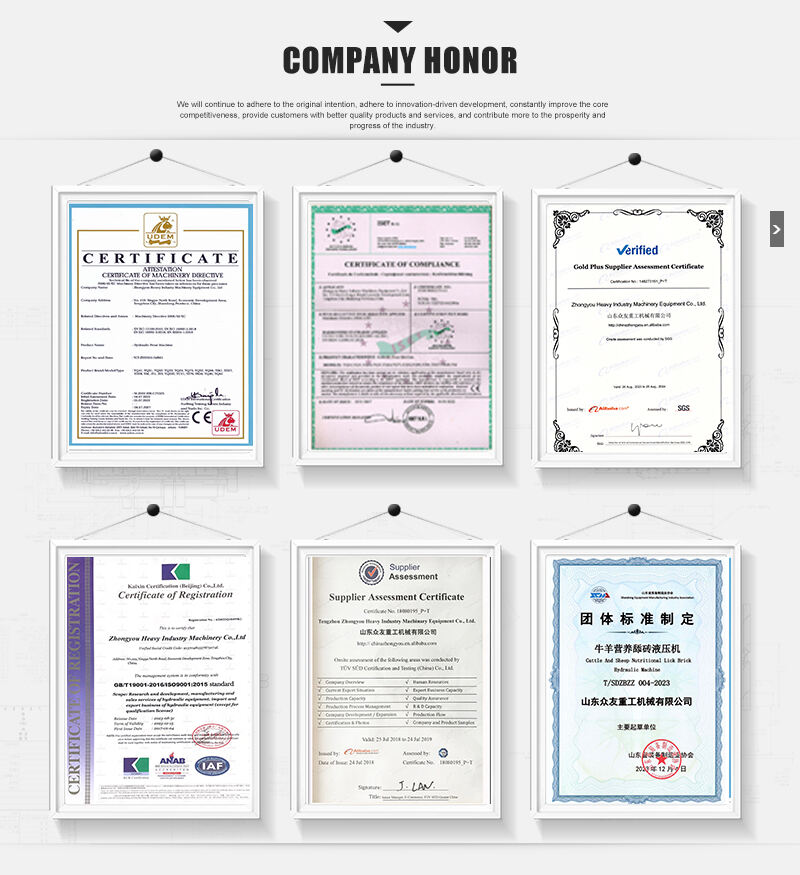

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

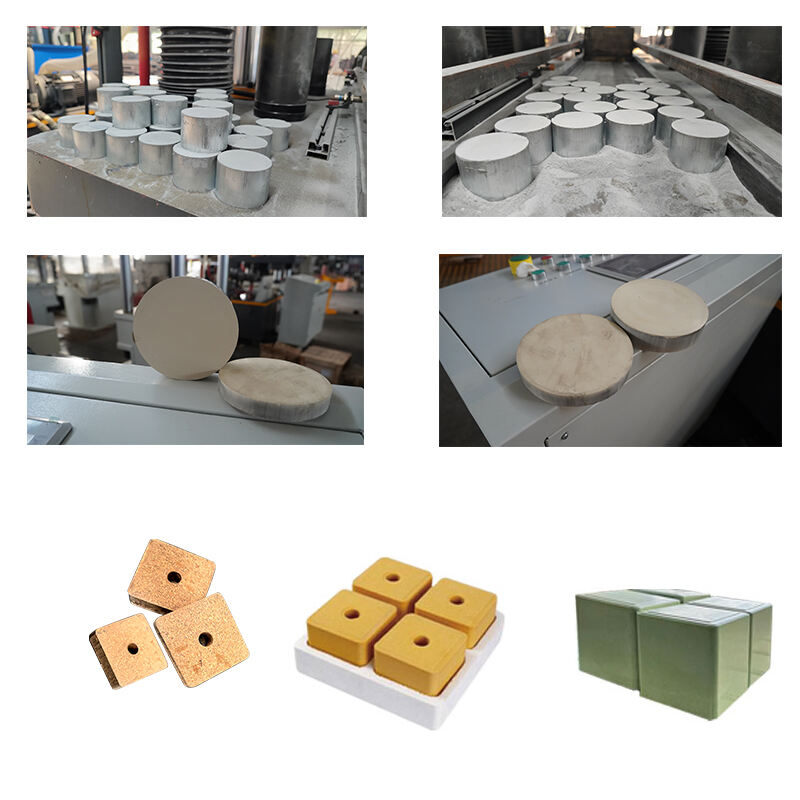

The 400 ton powder forming hydraulic press is a special equipment for pressing metal/non-metal powders (such as iron powder, copper powder, ceramic powder, etc.) into desired shapes in a mold. Its core function is to make the powder particles compactly stacked through high-pressure molding (cold or warm pressing) to form a blank with certain strength and precision, which will provide the basis for the subsequent sintering, machining and other processes.

400 tons powder molding hydraulic press is mainly used for the production of powder products with medium size, complex shape or high precision requirements, typical fields include:

Powder metallurgy: gears, bearing rings, cams, connecting rods and other metal structural parts (alternative to traditional forging/cutting processing, cost reduction);

Cemented carbide: cutting tools (e.g. milling cutters, drills), mold inserts (high hardness, wear resistance);

Electronic ceramics: capacitor substrates, insulators, sensor housings (high precision, good insulation);

Magnetic materials: motor cores, transformer ferrites (high permeability, low loss);

Friction materials: brake pads, clutch plates (wear-resistant, high temperature resistant).

Its core functions include:

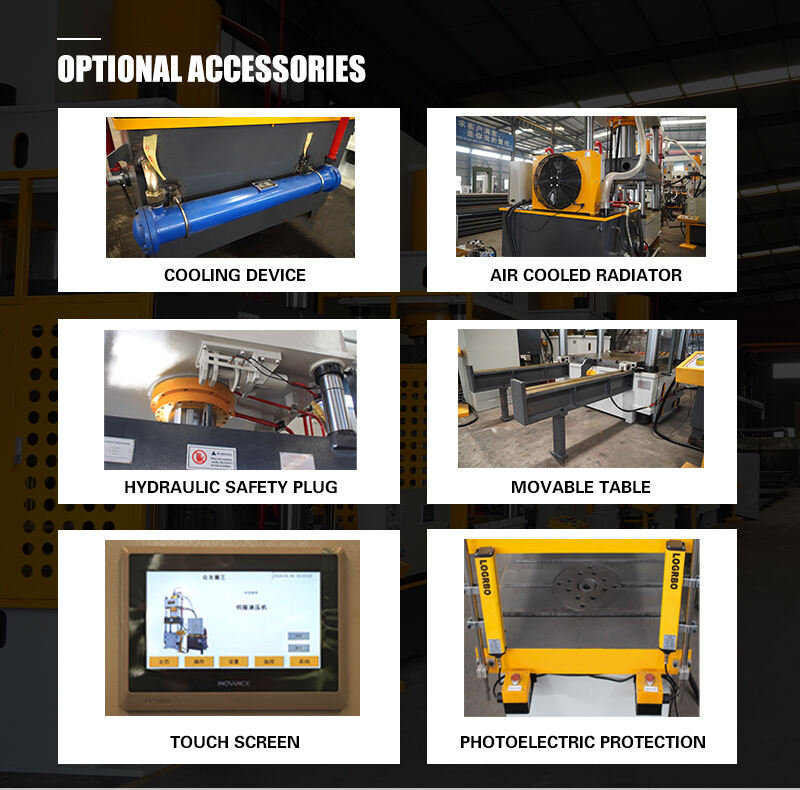

High-precision pressing: PLC or servo control system is adopted, with adjustable pressure, speed and stroke to ensure the dimensional accuracy of products within ±0.02mm. Complex shape molding: support two-way pressure, floating pressing, core extraction and demolding processes, can produce internal cavities, concave and convex surfaces and other complex structure products.

Automatic production: optional automatic feeding, online inspection, parts storage rotary table and other devices to realize single-operator operation or multi-machine linkage.

Equipment Advantages

High-density products: The two-way pressurization technology makes the density of products reach 6.8-7.2g/cm³, and the strength is increased by 20%.

Low energy consumption: variable energy-saving hydraulic system, standby power consumption is reduced by 40%, saving about 20,000 yuan in annual electricity costs.

Long life: 1 year warranty for key components, and the whole machine life is more than 10 years (average daily working hours of 8 hours).

Safety design: two-hand operation button, dead limit device, explosion-proof motor, in line with CE safety standards.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved