|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ41-100T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

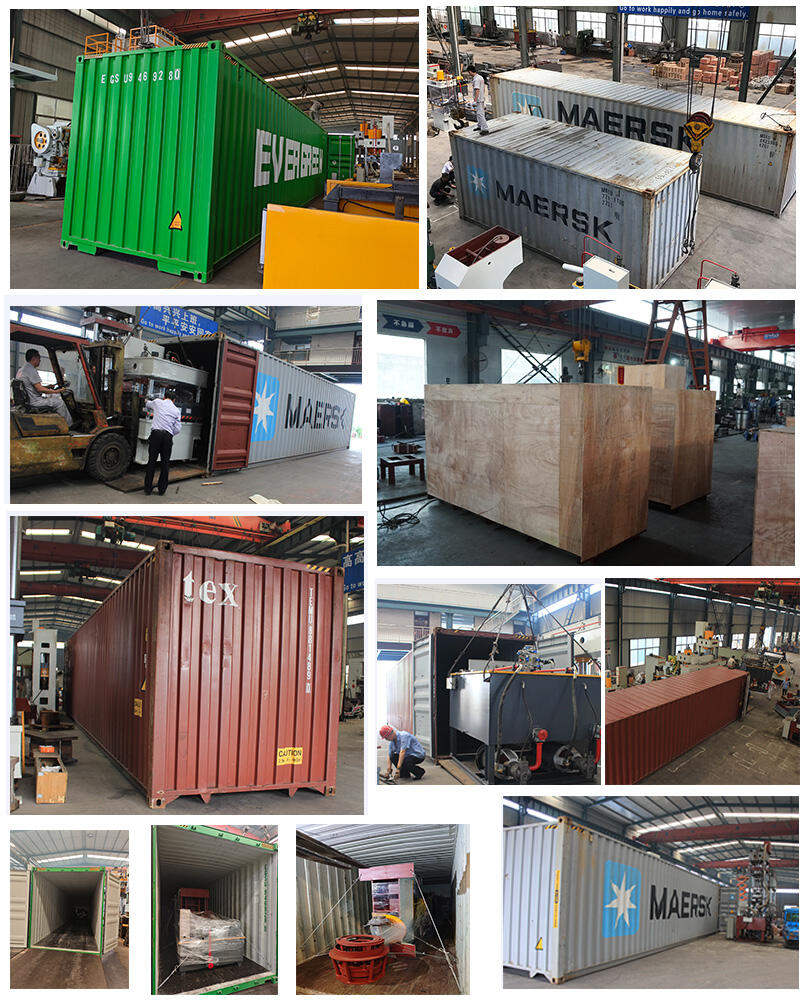

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

100 tons single arm hydraulic press with grating foot switch is a compact, high precision, easy to operate hydraulic molding equipment, combining the flexibility of the single arm structure, the accuracy of the grating measurement and the manual control function of the foot switch, is mainly used in the small It is mainly used for precision molding of metal/non-metal parts, mold research and matching, or laboratory research and development scenarios.

| SPECIFICATION | UNIT | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

| Nominal pressure | KN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 500 | 500 | 500 |

| Opening height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Down speed | mm/s | 16 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Table size L-R | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Table size F-B | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Blanking hole diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

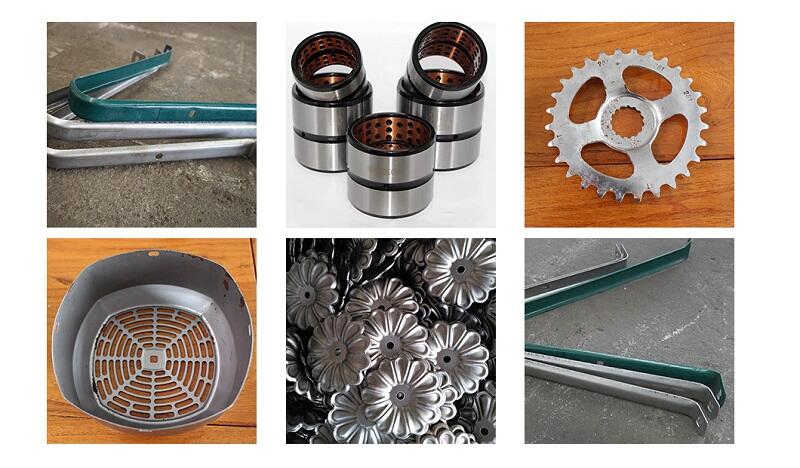

1. Small metal parts forming

Stamping: Stainless steel gaskets, copper washers, aluminum alloy nameplate drop, bending (such as electronic equipment shell fixed piece);

Stretching: thin-walled stainless steel cups, aluminum heat sink deep-drawing forming (need to be equipped with stretching pads to prevent wrinkles).

2. Mold processing and repair

Mold research and matching: small stamping mold (such as automotive lamp bracket mold) of the profile gap detection, through the scale real-time feedback to adjust the position of the upper mold;

Mold repair: repairing the mold after partial welding of the injection mold, the scale monitors the cavity depth deviation to ensure the repair accuracy.

3. Non-metallic material molding

Plastic molding: hot press molding of PVC gasket, acrylic decorative plate;

(Rubber products: vulcanization molding of seals, shock absorbing pads).

4. Laboratory and R&D scenarios

Material testing: compression testing of metal specimens, molding of ceramic blanks;

Small batch trial production: small batch trial production for new product development.

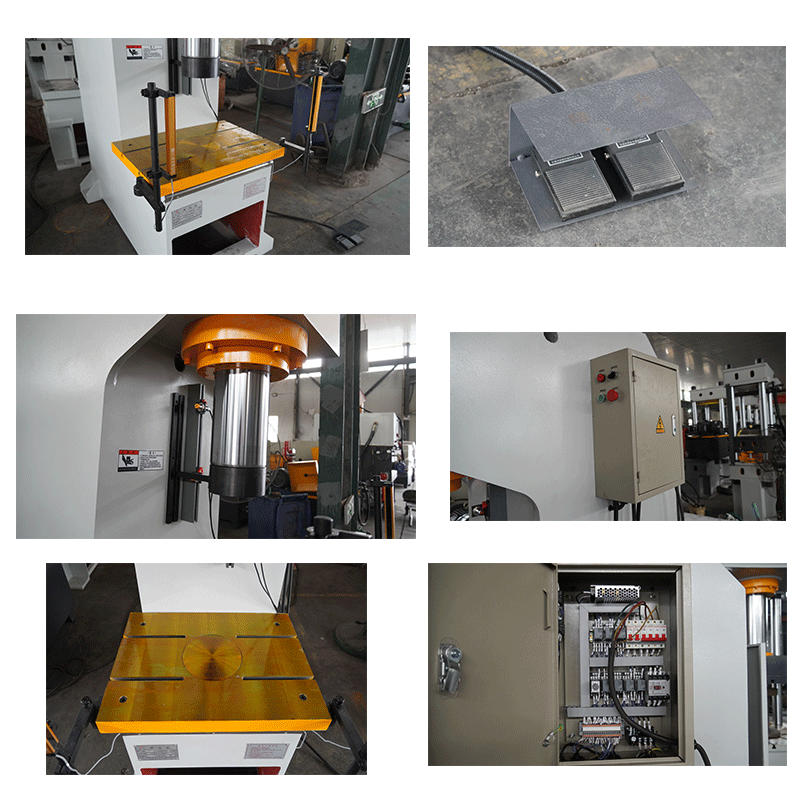

Single arm hydraulic press structure

C-type single-arm design: the body is welded with full steel plate and tempered to eliminate internal stress to ensure strength and rigidity.

Hydraulic system: adopts cartridge valve integration technology, reliable action and energy saving, some models are equipped with servo motor drive to further reduce energy consumption.

Control mode: Support PLC centralized control, with three operation modes: adjustment, manual and semi-automatic, and can realize fixed range or fixed pressure process.

Optical grating protection device

Function and Installation: Safety light grids are installed in the working area of the hydraulic press, forming a monitoring barrier to prevent personnel from accidentally entering the danger zone.

Safety linkage: integrated with the control system, real-time emergency stop is triggered to ensure safe operation. Regular cleaning of the grating surface to prevent dust from affecting detection accuracy.

Foot switch control

Operation standardization: Foot switch as a manual control device allows the operator to control the slide downward with his feet, which conforms to the two-hand operation standard and enhances safety.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved