|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YC21-125T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

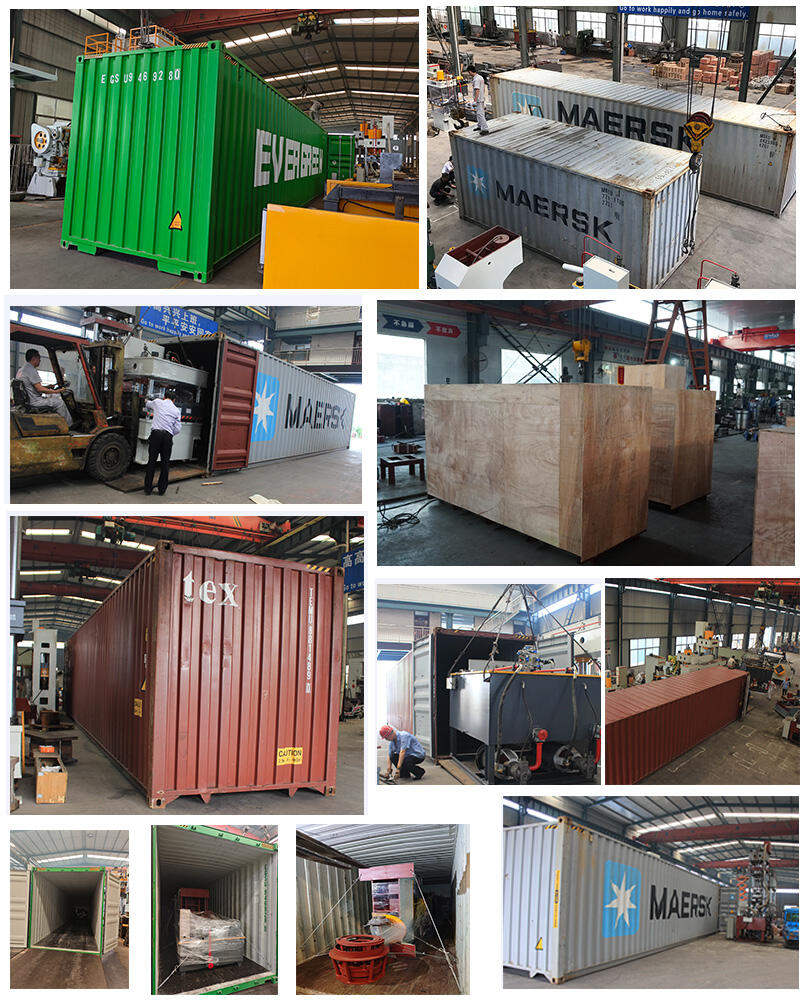

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

This mechanical punch press rotates the flywheel driven by the main motor, which drives the gears, crankshaft (or eccentric gears), connecting rods and other components through the clutch, converting the circular motion into the linear motion of the slider, thus generating the punching force.When the press works, the material is placed between the upper and lower molds, and the up and down movement of the slider exerts pressure on the material, causing it to produce plastic deformation, and completing the processing of cutting, punching, and stretching.

|

Parameters of Mechanical Punching Machines |

|||||||||

|

Model |

YC21-10 |

YC21-16 |

YC21-25 |

YC21-40 |

YC21-63 |

YC21-80 |

YC21-100 |

YC21-125 |

YC21-160 |

|

Nominal Force |

100KN |

160KN |

250KN |

400KN |

630KN |

800KN |

1000KN |

1250KN |

1600KN |

|

Nominal Force Stroke |

2MM |

3MM |

3MM |

4MM |

4MM |

5MM |

6MM |

8MM |

10MM |

|

Stroke of Slider |

50MM |

60MM |

70MM |

100MM |

100MM |

120MM |

130MM |

130MM |

140MM |

|

Frequency of slide stroke (times/minute) |

140 |

130 |

70 |

45 |

55 |

50 |

45 |

45 |

40 |

|

Max. closed height |

155mm |

200mm |

220mm |

235mm |

245mm |

270mm |

270mm |

310mm |

330mm |

|

Closed Height Adjustment |

30mm |

40mm |

40mm |

50mm |

50mm |

60mm |

60mm |

60mm |

70mm |

|

Throat Depth |

120mm |

170mm |

170mm |

230mm |

230mm |

260mm |

280mm |

280mm |

320mm |

|

Effective Size of Worktable (LR x FB) |

350*220mm |

450*280mm |

520*320mm |

640*410mm |

700*430mm |

750*460mm |

900*580mm |

1000*580mm |

1100*700 |

|

Size of Slider (LR x FB) |

145*100mm |

175*135mm |

195*175mm |

235*200mm |

315*220mm |

320*230mm |

345*260mm |

400*320mm |

500*380 |

|

Diameter of the die hole (diameter×depth) |

30*40mm |

40*50mm |

40*60mm |

50*60mm |

50*60mm |

60*70mm |

60*70mm |

70*70mm |

70*70mm |

|

Motor Power |

1.1kw |

1.5kw |

2.2kw |

3.0kw |

4.0kw |

7.5kw |

7.5kw |

11kw |

15kw |

|

Overall Dimension (L×W×H) |

0.8*0.6*1.5m |

0.9*0.7*1.7m |

1.1*0.8*2m |

1.5*1.1*2.3m |

1.6*1.1*2.5m |

1.6*1.3*2.6m |

1.9*1.3*2.7m |

1.9*1.4*2.9m |

2.1*1.9*3.1m |

|

Machine Weight |

300kg |

600kg |

1000kg |

2050kg |

2700kg |

3700kg |

5000kg |

6900kg |

9800kg |

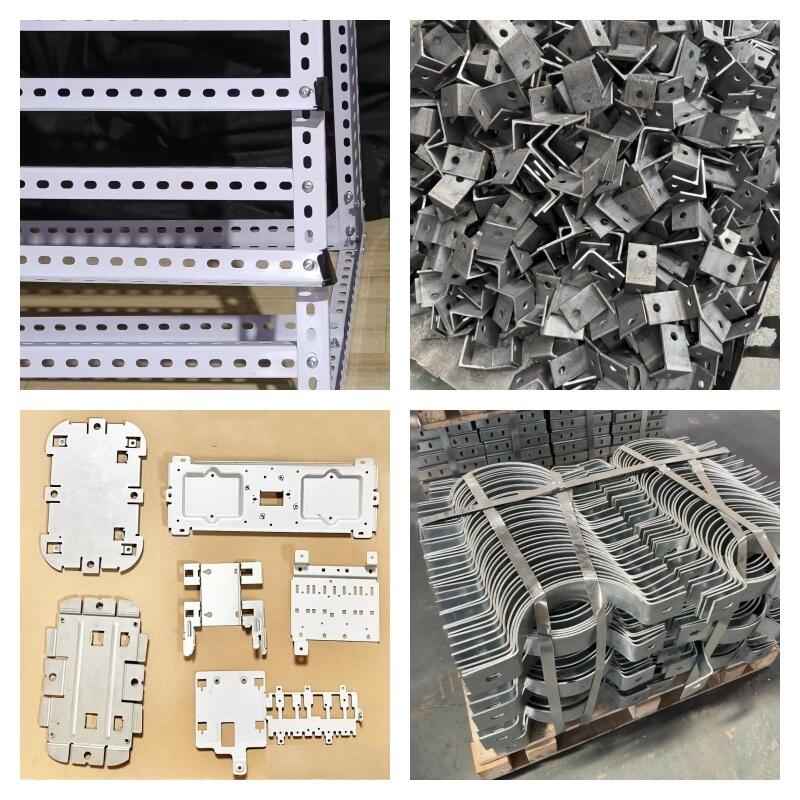

Processing range: suitable for punching, shearing, forming, stretching, trimming, fine punching, shaping, riveting and extruding of metal sheets.

Application areas: Widely used in stamping and molding processing of electronics, communications, computers, household appliances, furniture, transportation (automobiles, motorcycles, bicycles), hardware parts and other industries.

Automated production: it can be equipped with automatic feeding device to realize the functions of feeding error detection, pre-cutting, pre-breaking, etc. to improve production efficiency and reduce costs.

High rigidity and high precision: the frame of the punch press is usually welded with steel plate and heat-treated to eliminate internal stresses and ensure the long-term stable work of the equipment.The main parts such as crankshaft, gears, transmission shafts, etc. are hardened heat-treated and milled, with high wear resistance and long-term performance stability.

Slider adjustment mechanism: the slider adjustment is divided into manual and electric two ways, easy and reliable adjustment, precision up to 0.1mm.

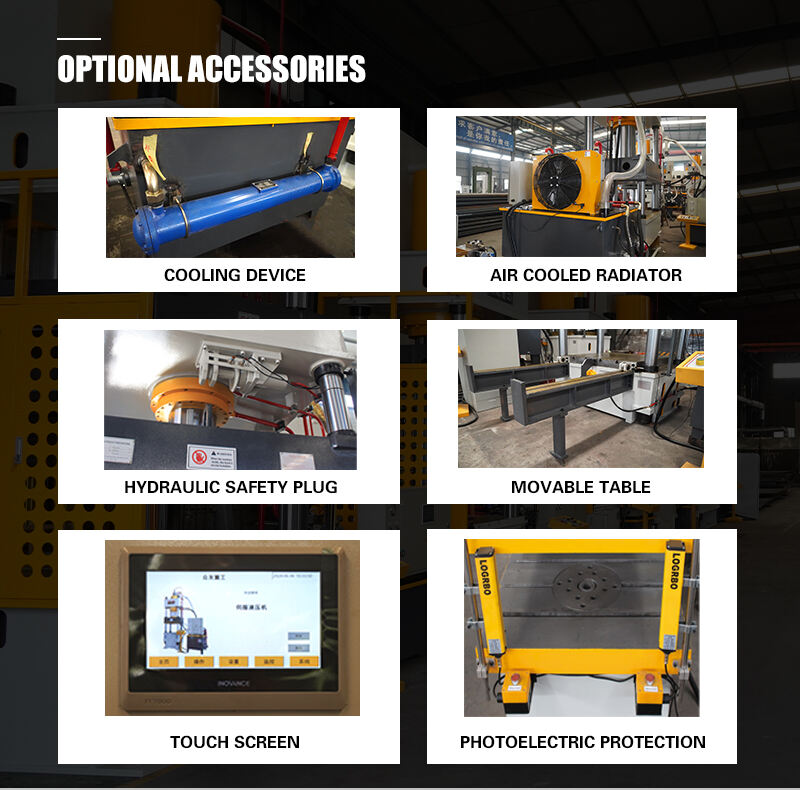

Safety device: Adopt high sensitivity clutch/brake combination device, equipped with duplex electromagnetic control valve and overload protection device, to ensure the accuracy and safety of high-speed movement and stopping of the slider.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing press machine user manuals to facilitate user learning on how to operate and maintain the press machine.

We provide a full set of hydraulic press equipment with many mature design solutions and successful customer cases. We also provide customized service with molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved