Home / Product / C type press

|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ41-20T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

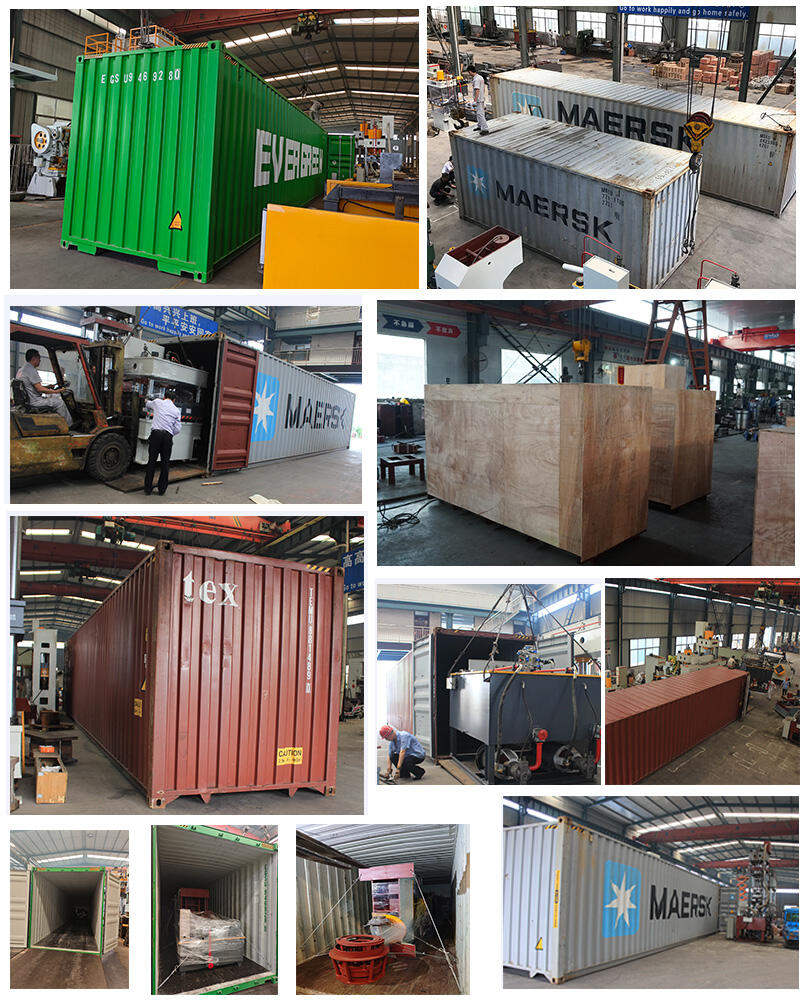

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

Single-arm hydraulic press adopts C-type single-arm structure, the machine body consists of a single column with upper and lower cross beams, forming an open operation space.Its working principle is based on Pascal's law, through the hydraulic pump to the integrated valve block, through the check valve and relief valve distribution to the upper or lower chamber of the cylinder, drive the piston movement to realize the pressing, stretching and other processes.

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

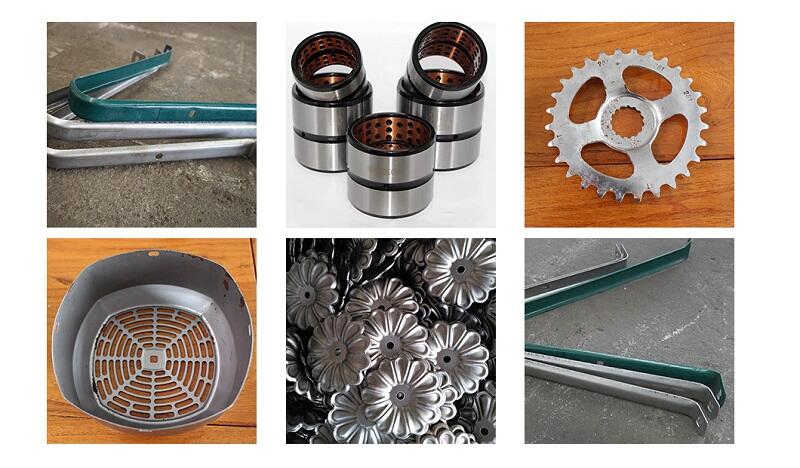

Genus Processing Fields

Shaft parts correction: such as motor shaft, transmission shaft straightness correction.

Bushing press-fitting: automatic detection and alarm function ensures accurate press-fitting force and 100% product qualification rate.

Sheet metal forming: stretching and bending of automobile sheet metal parts and electrical appliance housings.

Powder metallurgy pressing: high-density circuit boards, line-up die-cutting process.

Non-metallic material processing

Plastic products pressing: such as appliance shell, daily necessities molding.

Vulcanization of rubber products: hot press molding of tires and seals.

Special industry applications

Light textile machinery: press fitting and calibration of textile machinery parts.

Electronic and electrical appliances: motor rotor and stator press-fitting, plug-in parts molding.

Aerospace: precision pressing of small composite components

Structural Advantages

C-shape design: Utilizing the space on three sides to widen the working range, suitable for large-sized workpieces or shaped parts processing.

High rigidity guiding: Adopt four-column guide pillar guiding or precision guide sleeve to control the vertical accuracy of the movable plate to ensure the parallelism of pressing ≤ 0.08mm.

Functional flexibility

Multi-process adaptation: Support two kinds of molding processes: fixed-pressure and fixed-process, which can complete the action of ejecting, stretching, bending, embossing, and so on.

Adjustable parameters: working pressure, pressing speed, no-load fast down stroke, etc. can be adjusted according to process requirements to meet diversified production.

Hand and foot linkage operation: Simplify the operation process and enhance the production efficiency, especially suitable for single piece or small batch production.

Safety and Reliability

Overload protection: Some models are equipped with hydraulic overload protection device to prevent equipment damage.

Sealing and lubrication: the column and piston rod are quenched and plated with copper and hard chrome, with high wear-resistant surface; the oil inlet of the oil pump is equipped with a filtering device to prolong the life of the valve body.

Safety protection: photoelectric protection device, emergency stop button, etc. to ensure operational safety.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved