|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

VTC80 |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

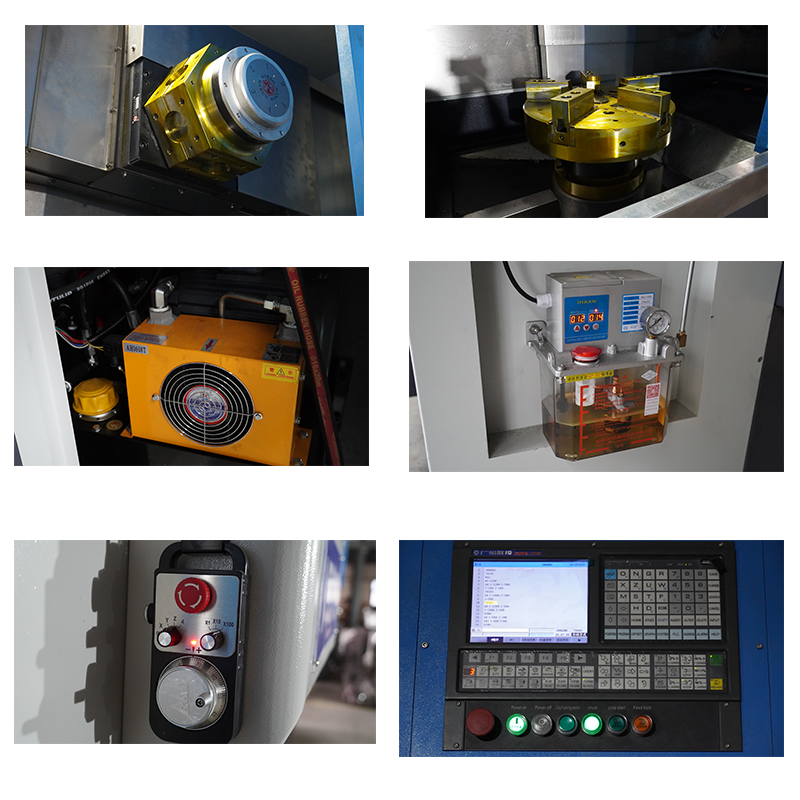

VTC80 CNC Vertical Turning Lathe is a high-precision CNC machine for machining large rotary body parts, mainly used in batch or single piece production, applicable to automotive, wind power, aerospace, mold and other fields of precision parts processing.

| Vertical Lathe Parameters | |||||

| Item | Specification | Unit | VT45 | VT65 | VT75 |

| Machining Capacity | Maximum Swing Diameter | mm | ∮560 | ∮650 | ∮750 |

| Maximum Cutting Diameter | mm | ∮450 | ∮600 | ∮700 | |

| Spindle | Spindle End Face Type | Plain | Plain | Plain | |

| Spindle Speed | rpm | 100-2000 | 100-1000 | 100-1000 | |

| Chuck Outer Diameter | mm | 500 | 500 | 610 | |

| Tool Turret | Tool Capacity | pc | Horizontal Eight-Position | Horizontal Eight-Position | Horizontal Eight-Position |

| Travel | X-Axis Travel | mm | 400 | 420 | 700 |

| Z-Axis Travel | mm | 500 | 500 | 700 | |

| Hydraulic Unit | Oil Tank Capacity | L | 40 | 40 | 40 |

| Hydraulic Motor | kw | 2.2 | 2.2 | 2.2 | |

| Motor | Spindle Servo Motor | kw | 15 | 18.5 | 22 |

| Accuracy | Repetition Accuracy | mm | ±0.008 | ±0.005 | ±0.005 |

| Positioning Accuracy | mm | ±0.008 | ±0.008 | ±0.008 | |

| Machine Dimensions (LWH) | Length Width Height | mm | 2200*2300*2600 | 2150*2210*2970 | 2700*2100*3200 |

| Weight (Including Accessories) | kg | 5000 | 7000 | 9500 | |

| Power Requirements | Power Supply | 3¢-AC 380V 50HZ±5% | |||

| The machine has leakage protection and power-off protection | √ | ||||

| Machine Work Status Indicator (Three-Color Light) | √ | ||||

| The machine operates stably under the following conditions | Ambient Temperature 5~38° | ||||

| bient Humidity<85% | |||||

| Machine Noise Complies with National Standards | √ | ||||

| Remarks | ☆The equipment uses fully enclosed protection; the protective devices are safe and reliable, and should comply with GB15760-1995 General Technical Regulations for Safety Protection of Metal Cutting Machine Tools. ☆Various hydraulic, pneumatic, and water pipe directions are marked, along with the working range of various instruments and the medium type. ☆The diameter of the hydraulic chuck and the tool turret positions can be selected according to machining requirements. |

||||

Automobile parts manufacturing

Wheel hub machining: support rough and fine turning of aluminum alloy wheel hubs, complete internal and external cylindrical surfaces, end faces, groove cutting and other processes in one clamping.

Brake system: processing brake drums, flywheel shells, clutch pressure plates, etc., to meet the requirements of high-precision dimensional consistency.

Transmission components: suitable for efficient machining of complex shaped parts such as differential housing, transmission case, etc.

General Mechanical Processing

Disc parts: such as flanges, gear blanks, pump bodies, etc. Vertical clamping avoids the deformation problem of horizontal machining.

Short shaft parts: such as motor shafts, transmission shafts, etc., supporting the integrated machining of end faces, external rounds and keyways.

Heavy cutting scenario

Some models are equipped with reinforced spindles and eight-station tool holders, which can withstand large cutting volume and are suitable for rough machining of casting blanks.

The core advantages of VTC80 CNC vertical lathe are reflected in automation, precision and efficiency:

High-precision machining: through the closed-loop control and thermal compensation function of the CNC system, the positioning accuracy can reach ±0.005mm, and the repetition positioning accuracy is ±0.003mm, which meets the requirements of IT6-IT7 grade surface roughness.

Multi-process integration: with the power turret or Y-axis (radial feed), it can realize "turning-milling-drilling-tapping" compound machining, reduce the number of clamping times and improve the consistency of parts.

High-efficiency production: rapid traverse speed, automatic tool changer and constant line speed control (spindle speed adjusts automatically with the change of workpiece diameter) significantly shorten the machining time of a single piece, which is suitable for mass production.

Intelligent operation: supports graphical programming (e.g. ShopMill), adaptive feed (automatic adjustment of speed/feed according to cutting force), self-diagnosis of faults (real-time alarms and prompts), etc., which reduces the threshold of operation.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We provide a full set of hydraulic press equipment and CNC vertical lathe, with many mature design solutions and successful customer cases. We can also provide customized service, provide molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved