|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ32-630T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

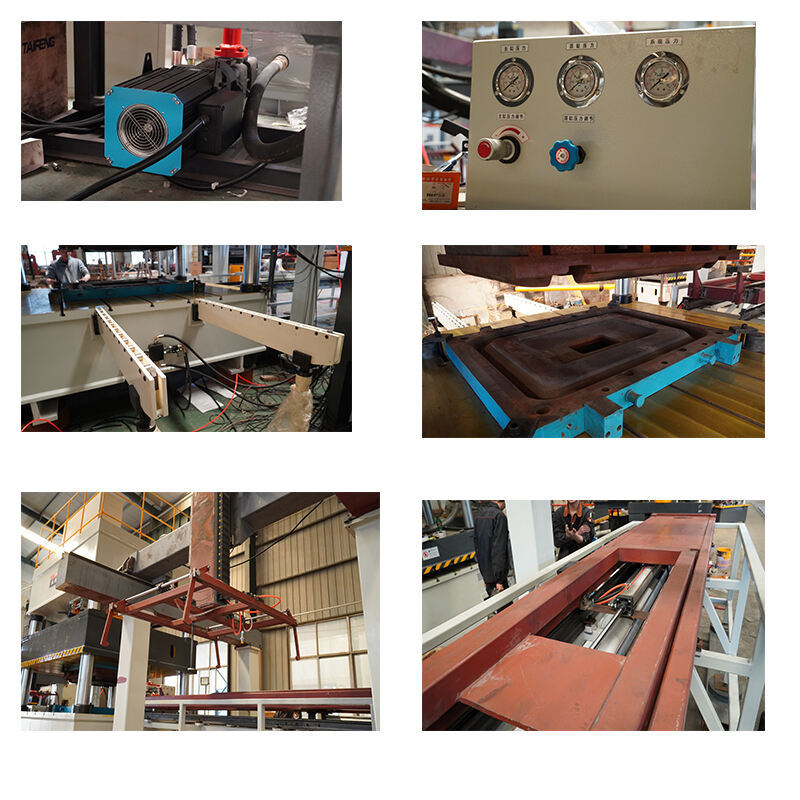

The core objective of the train door shaping hydraulic press is to solve the problems of "jamming, air leakage, poor closure" caused by the deformation of the door.Its working principle is based on the pressure control of the hydraulic system and the synergy of the mechanical structure: through a number of groups of hydraulic cylinders on different parts of the door to apply uniform, controllable corrective force, with adjustable positioning fixtures, the deformation of the door frame, door panels gradually corrected to the design size, and at the same time repair the sealing strip groove, door stops and other key parts of the accuracy, to ensure that the door and the body of the car a tight fit, switching and flexible.

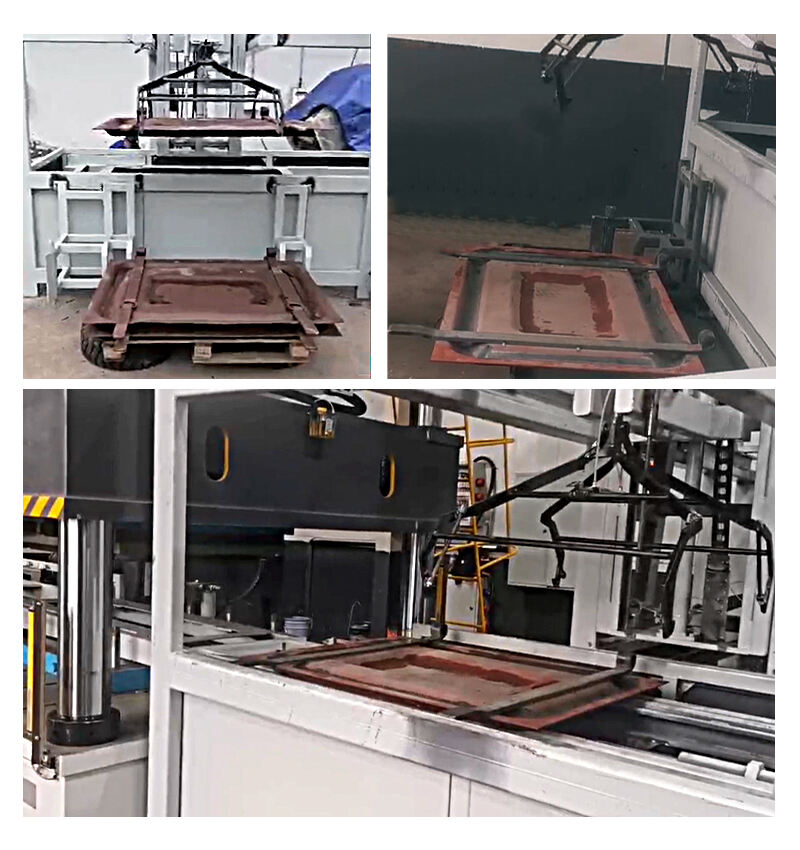

Train door panel repair

Proofreading of deformed and dented door panels to restore their flatness and dimensional accuracy.

Repairing scratches, pits and other defects on the surface of door panels by mold pressing.

Door Panel Press Molding

Pressing and molding metal sheets into specific shapes of door panels to meet the design requirements of different models.

Supports continuous processing with multiple steps, such as stretching, calibrating, and trimming.

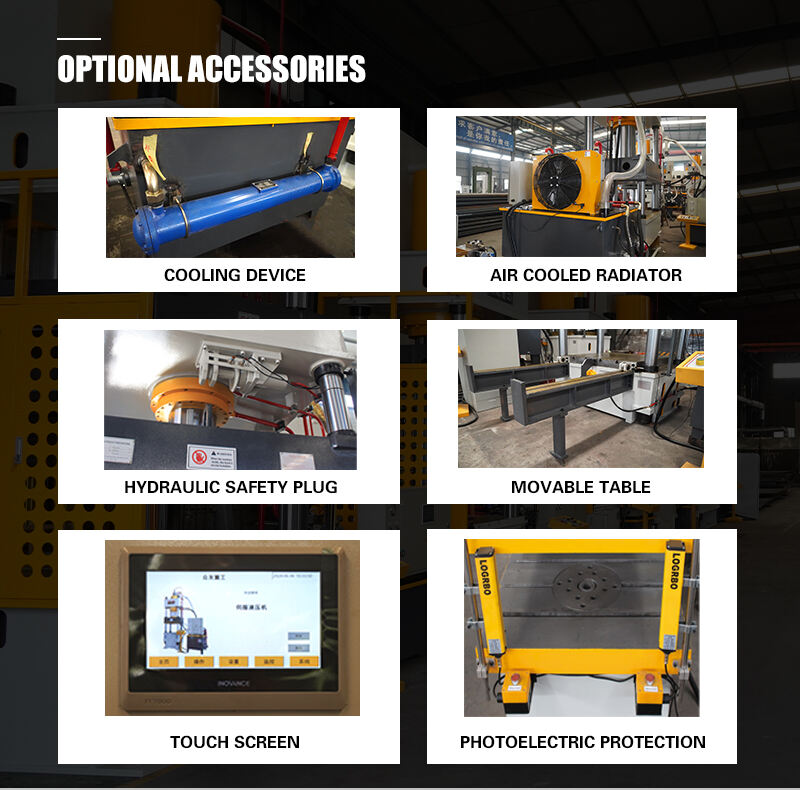

Other sheet metal processing

Suitable for proof-forming and pressing of metal sheets in automotive, marine, aerospace and other fields.

Main Function: Correcting the door panel's depression, bending and twisting caused by stamping rebound, transportation collision, long-term use or welding deformation (e.g., deformation after assembling the door skeleton and skin).

Application Scenario: Manufacturing: After the door is stamped and molded, the shape deviation is caused by the elastic return of the material (rebound).rebound) leads to shape deviation, which needs to be corrected by the shaping press;

Maintenance: in vehicle sections or maintenance bases, doors are repaired due to deformation caused by accidents (such as scratches), aging or fatigue;

Special requirements: door shaping for lightweight materials such as aluminum alloy, stainless steel, etc. (the ductility and brittleness of the material need to be taken into account).

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved