เครื่องอัดไฮดรอลิกคืออุปกรณ์ที่ใช้แรงดันสูงในการขึ้นรูปโลหะและผลิตภัณฑ์ที่คล้ายกัน โดยในบรรดาเครื่องอัดไฮดรอลิกต่างๆ เครื่องอัดไฮดรอลิกแบบสี่เสามีความพิเศษเนื่องจากให้แรงที่คงที่และแม่นยำสูง เครื่องเหล่านี้จึงเหมาะสำหรับงานที่ต้องการความละเอียดแม่นยำเป็นพิเศษ ที่ ZHONGYOU เราออกแบบเครื่องอัดไฮดรอลิกแบบสี่เสาที่สามารถขึ้นรูปทุกอย่างได้อย่างเหมาะสม ไม่มีข้อผิดพลาดและสมบูรณ์แบบเสมอ เมื่อใดก็ตามที่คุณต้องการความแม่นยำสูงสุด เรามีเครื่องจักรเหล่านี้ไว้บริการคุณ

เหตุใดเครื่องอัดไฮดรอลิกแบบสี่เสาจึงเหมาะสำหรับการประยุกต์ใช้งานด้านการขึ้นรูปที่ต้องการความแม่นยำ

เครื่องอัดไฮดรอลิกแบบ 4 คอลัมน์นั้นเหมาะอย่างยิ่งสำหรับงานขึ้นรูปที่ต้องการความแม่นยำ เนื่องจากช่วยให้ทุกอย่างคงที่และมั่นคงในขณะทำงาน ลองนึกภาพการอัดชิ้นส่วนโลหะด้วยเครื่องจักรขนาดใหญ่ หากแรงที่ใช้อัดไม่สม่ำเสมอ หรือเครื่องสั่น โลหะนั้นอาจโค้งผิดรูปหรือเสียหายได้ แต่ด้วยระบบ 4 คอลัมน์ แรงกดจะกระจายอย่างสม่ำเสมอจากทุกทิศทาง ส่งผลให้โลหะรักษารูปร่างตามที่ออกแบบไว้อย่างแม่นยำ ตัวอย่างเช่น ความผิดพลาดเพียงเล็กน้อย เช่น ชิ้นส่วนที่ไม่พอดีกับอะไหล่รถยนต์ อาจก่อปัญหาในระยะยาวได้ เครื่องอัดแบบ 4 คอลัมน์จาก ZHONGYOU จะรับประกันว่าชิ้นส่วนของคุณจะถูกผลิตออกมาอย่างถูกต้องทุกครั้ง นอกจากนี้ เครื่องเหล่านี้ยังมาพร้อมโครงสร้างที่แข็งแรง ไม่สั่นหรืองอ ซึ่งสำคัญมาก เพราะหากคุณกำลังทำงานที่ต้องการความละเอียดแม่นยำ การเคลื่อนไหวเพียงเล็กน้อยก็สามารถทำให้ผลิตภัณฑ์เสียหายได้

อีกหนึ่งข้อดีคือ เครื่องอัดแบบสี่เสาสามารถจัดการกับชิ้นงานที่มีขนาดและรูปร่างต่างๆ ได้อย่างง่ายดาย ไม่ว่าจะเป็นชิ้นส่วนขนาดเล็กหรือแผ่นโลหะขนาดใหญ่ เครื่องจักรสามารถปรับตัวและยังคงให้แรงอัดอย่างต่อเนื่อง ความหลากหลายเช่นนี้ช่วยประหยัดทั้งเวลาและต้นทุน เนื่องจากเครื่องจักรเพียงเครื่องเดียวสามารถทำงานหลายอย่างได้โดยไม่เสียความแม่นยำ นอกจากนี้ เครื่องอัดของ ZHONGYOU ยังมาพร้อมระบบควบคุมการเคลื่อนไหวที่ลื่นไหล ซึ่งหมายความว่า เมื่อจำเป็น เครื่องจะเคลื่อนที่อย่างช้าๆ และระมัดระวัง แทนที่จะกระทำทั้งหมดในครั้งเดียว การเคลื่อนไหวอย่างแผ่วเบาช่วยให้สามารถสร้างส่วนที่เปราะบางได้โดยไม่เกิดการแตกหักหรือตำหนิ บางเครื่องจักรออกแรงเร็วเกินไป ทำให้วัสดุแตกร้าวหรือทิ้งร่องรอยที่ไม่สวยงาม เครื่องอัดไฮดรอลิกแบบสี่เสาของเราป้องกันปัญหาเหล่านี้ได้ โครงสร้างยังช่วยให้การวางและนำวัสดุออกทำได้ง่าย ผู้ปฏิบัติงานไม่ต้องดิ้นรนกับเครื่อง หรือเสี่ยงต่อการทำให้ผลิตภัณฑ์เสียหาย ซึ่งเป็นประโยชน์อย่างมากในโรงงานที่มีการทำงานหนักและรวดเร็ว ทั้งหมดนี้คือเหตุผลที่เครื่องอัดแบบสี่เสา เครื่องอัดไฮดรอลิก ได้ทำให้กระบวนการขึ้นรูปที่ต้องการความแม่นยำปลอดภัยและดีขึ้น

อะไรทำให้เครื่องอัดไฮดรอลิกสี่เสาเป็นสิ่งจำเป็นสำหรับการขึ้นรูปที่มีความแม่นยำและคุณภาพสูง?

เครื่องอัดไฮดรอลิกสี่เสานั้นมีมากกว่าแค่แรงกดที่สม่ำเสมอ แต่ยังช่วยให้ผลิตภัณฑ์มีลักษณะและการทำงานที่ดีขึ้นด้วย เมื่อต้องการชิ้นส่วนที่มีคุณภาพสูง ทุกๆ มิลลิเมตรมีความสำคัญ ไม่ว่าจะเป็นขอบเล็กๆ หรือพื้นผิวเรียบทั้งหลาย เครื่องอัดสี่เสา ZHONGYOU ทำให้มั่นใจได้ว่าโลหะจะไม่เคลื่อนที่หรือเลื่อนขณะขึ้นรูป ซึ่งหมายความว่าชิ้นส่วนที่ได้ออกมาจะสะอาดและสมบูรณ์แบบ โดยไม่จำเป็นต้องแก้ไขเพิ่มเติมหรือขัดเงาอีก นั่นจึงช่วยประหยัดทั้งเวลาและต้นทุน อีกเหตุผลหนึ่งที่ทำให้เครื่องเหล่านี้ขาดไม่ได้คือโครงสร้างที่แข็งแรง คานรองรับสี่จุดช่วยป้องกันไม่ให้ส่วนบนของเครื่องบิดหรือโยกคลอนภายใต้ภาระหนัก ส่งผลให้แรงกดคงที่เหมาะสม ซึ่งมีความสำคัญอย่างยิ่งกับชิ้นส่วนที่ต้องประกอบพอดีกันอย่างแม่นยำ

นอกจากนี้ วิธีที่ ZHONGYOU สร้างเครื่องอัดเหล่านี้ทำให้มีอายุการใช้งานยาวนาน การใช้งานหนักหรืองานขนาดใหญ่จะไม่ทำให้เครื่องเสียเร็ว เพราะเมื่อเครื่องจักรมีความน่าเชื่อถือ การผลิตก็จะดำเนินไปอย่างราบรื่น และลูกค้าก็แทบไม่มีปัญหาในการได้รับผลิตภัณฑ์ที่มีคุณภาพตรงเวลา เครื่องอัดเหล่านี้ยังมาพร้อมระบบควบคุมที่ช่วยให้ผู้ปฏิบัติงานสามารถกำหนดแรงดันและความเร็วที่ต้องการได้อย่างแม่นยำ ซึ่งการควบคุมนี้มีความสำคัญอย่างยิ่งต่องานที่ต้องการความละเอียด เช่น การขึ้นรูปแผ่นโลหะหรือชิ้นส่วนที่ละเอียดอ่อน ตัวอย่างเช่น หากแรงดันหรือความเร็วสูงเกินไป ชิ้นงานอาจแตกร้าวหรือโค้งงอผิดรูป ด้วยเครื่องอัดแบบสี่เสา ผู้ปฏิบัติงานสามารถตั้งค่าที่เหมาะสมได้อย่างแม่นยำเพื่อลดข้อผิดพลาดจากมนุษย์ นอกจากนี้ พื้นที่เปิดโล่งภายในโครงแบบสี่เสา ยังช่วยให้จัดการกับวัสดุได้สะดวกยิ่งขึ้น เครื่องมือสามารถติดตั้งได้ดีขึ้น และพนักงานสามารถสังเกตเห็นสิ่งที่เกิดขึ้นระหว่างกระบวนการขึ้นรูปได้อย่างชัดเจน ซึ่งเป็นวิธีสำคัญในการตรวจพบปัญหาแต่เนิ่นๆ และแก้ไขได้อย่างรวดเร็ว

และ ZHONGYOU มีประสบการณ์มากในการผลิตเครื่องจักรเหล่านี้ ดังนั้นเราจึงรู้ดีว่าผู้คนให้คุณค่ากับความแม่นยำและคุณภาพอย่างไร เครื่องกดแบบสี่เสาและแบบเฟรม C ของเราเป็นตัวอย่างของดีไซน์ที่แข็งแรงในพื้นที่ขนาดกะทัดรัด สามารถรองรับการขึ้นรูปและการตอกด้วยระบบไฮดรอลิกได้ นี่คือสิ่งที่เกิดขึ้นเมื่อคุณได้ชิ้นส่วนที่สมบูรณ์แบบเสมอ เครื่องจักรเหล่านี้ไม่ได้แค่กดโลหะเท่านั้น แต่ยังสร้างชิ้นส่วนที่มีอายุการใช้งานยาวนานกว่าและทำงานได้ดีขึ้นในโลกแห่งความเป็นจริง นี่จึงเป็นเหตุผลที่เครื่องกดไฮดรอลิกแบบสี่เสาได้กลายเป็นสิ่งจำเป็นอย่างแท้จริงสำหรับงานขึ้นรูปความแม่นยำสูง

ปัญหาทั่วไปของเครื่องกดไฮดรอลิกแบบสี่เสาและแนวทางแก้ไขสำหรับชิ้นส่วนความแม่นยำ

เช่น ZHONGYOU เครื่องกดน้ํามันสี่คอลัมน์ เป็นเครื่องจักรที่ยอดเยี่ยมสำหรับการขึ้นรูปเย็นความแม่นยำสูงนี้ แต่แม้แต่เครื่องจักรรุ่นท็อปเองก็อาจประสบปัญหาในการผลิตชิ้นส่วนที่มีความแม่นยำสูงมากได้ ตัวอย่างหนึ่งคือปัญหาแรงกดที่ไม่สม่ำเสมอระหว่างกระบวนการกด หากแรงกดไม่กระจายอย่างเท่าเทียมทั่วทั้งชิ้นงานโลหะ รูปร่างที่ได้อาจผิดเพี้ยนหรือไม่ได้ขนาดที่ถูกต้องพอดี ปัญหานี้อาจเกิดขึ้นได้หากเสาหลักจัดตำแหน่งไม่ตรง หรือโครงเครื่องไม่แข็งแรงพอที่จะรักษาระดับความมั่นคง ZHONGYOU จึงออกแบบเครื่องอัดลมนิวแมติกสำหรับงานโลหะ 60 ตันของตนให้มีโครงสร้างที่แข็งแกร่ง พร้อมเสาค้ำยัน ✓ การตรวจสอบความขนานของรางนำอย่างระมัดระวัง สิ่งเหล่านี้ช่วยให้มั่นใจว่าแรงกดจะถูกกระจายอย่างสม่ำเสมอ และโลหะจะถูกขึ้นรูปได้อย่างถูกต้องทุกครั้ง

อีกปัญหาหนึ่งอาจเกิดจากระบบไฮดรอลิกที่ทำงานช้าเกินไป เครื่องอัดอาจเคลื่อนไหวช้าเกินไปเมื่อน้ำมันภายในเครื่องไหลไม่สะดวก หรือหยุดทำงานทันที ซึ่งจะทำให้ชิ้นงานขึ้นรูปไม่สำเร็จ ZHONGYOU ใช้ชิ้นส่วนไฮดรอลิกขั้นสูง และควบคุมการไหลของน้ำมันโดยอัตโนมัติอย่างแม่นยำ ทำให้เครื่องดัดแผ่นโลหะของเราทำงานได้อย่างรวดเร็วและเสถียร กระบวนการผลิตจึงมีความเสถียร และลดข้อผิดพลาดในชิ้นงานสุดท้าย

บางครั้งเครื่องอัดอาจสึกหรอก่อนเวลาอันควรหากใช้งานหนักหรือใช้งานมากเกินไป แต่สามารถเปลี่ยนแปลงพฤติกรรมนี้ได้ ชิ้นส่วนต่างๆ เช่น ซีลและกระบอกสูบอาจสึกหรอ จนก่อให้เกิดการรั่วหรือสูญเสียแรงดัน การบำรุงรักษาตามกำหนดและการใช้อะไหล่แท้จาก Zhongyou จะช่วยให้เครื่องอัดแผ่นโลหะของคุณคงสภาพเหมือนใหม่ได้นานขึ้น การตรวจสอบและซ่อมแซมเชิงป้องกันจะช่วยหลีกเลี่ยงการเสียหายกะทันหัน และรักษาความแม่นยำของเครื่องอัดไว้ตลอดอายุการใช้งานที่ยาวนาน

ในที่สุด อุณหภูมิก็สามารถมีผลต่อประสิทธิภาพของเครื่องอัดได้ เช่น เมื่อเครื่องร้อนหรือเย็นเกินไป ชิ้นส่วนโลหะด้านในอาจขยายตัวหรือหดตัว ทำให้เกิดความคลาดเคลื่อนเล็กน้อยในกระบวนการขึ้นรูป เครื่องอัดไฮดรอลิกสี่เสา ทุกเครื่องอัดไฮดรอลิกสี่เสาของ ZHONGYOU ติดตั้งระบบระบายความร้อนและควบคุมอุณหภูมิ เพื่อรักษาระดับอุณหภูมิการใช้งานของเครื่องให้อยู่ในระดับเหมาะสมอยู่เสมอ ด้วยวิธีนี้ เครื่องอัดจึงสามารถผลิตชิ้นส่วนที่มีความแม่นยำได้ไม่ว่าจะมีฝนตกหรืออุณหภูมิ 110 องศาบนพื้นโรงงาน

ด้วยการรู้ปัญหาทั่วไปเหล่านี้ และอาศัยการออกแบบอันชาญฉลาดของ ZHONGYOU คุณสามารถแก้ปัญหาได้อย่างรวดเร็ว ซึ่งหมายความว่าคุณจะสามารถดำเนินการผลิตชิ้นส่วนที่แม่นยำต่อไปโดยใช้เครื่องอัดไฮดรอลิกสี่เสา ด้วยวิธีนี้ คุณจะสามารถส่งมอบงานที่เชื่อถือได้มากขึ้น ลดของเสีย และทำให้ลูกค้าพึงพอใจมากขึ้น

ข้อดีของเครื่องอัดไฮดรอลิกสี่เสาในโครงการขึ้นรูปที่ซับซ้อนและขนาดใหญ่

เมื่อบริษัทต่างๆ จำเป็นต้องผลิตชิ้นส่วนโลหะที่มีขนาดใหญ่หรือผลิตยาก มักจะหันมาใช้เครื่องอัดไฮดรอลิกแบบสี่เสาของ ZHONGYOU ไม่น่าแปลกใจเลยที่เครื่องอัดเหล่านี้เหมาะอย่างยิ่งสำหรับงานขึ้นรูปที่ซับซ้อนและมีปริมาณมาก เนื่องจากให้พลังงาน ความมั่นคง และการควบคุมได้อย่างดีเยี่ยม เครื่องจักรนี้มีความสมดุล เพราะมีสี่เสา จึงสามารถรองรับน้ำหนักที่มากได้โดยไม่โค้งหรือสั่นสะเทือน ซึ่งเป็นสิ่งสำคัญอย่างยิ่งในการแปรรูปแผ่นโลหะขนาดใหญ่หรือชิ้นงานที่หนา เพราะการเคลื่อนไหวเพียงเล็กน้อยก็อาจทำให้รูปร่างสุดท้ายผิดเพี้ยนได้

อีกเหตุผลหนึ่งที่ทำให้เครื่องอัดแบบสี่เสาได้รับความนิยมคือ ความสามารถในการกระจายแรงดันอย่างเท่าเทียมกันในทุกทิศทาง เสาสี่ต้นช่วยยึดแผ่นอัดให้มั่นคง ป้องกันการเอียง และการรองรับที่แม่นยำนี้สามารถผลิตชิ้นส่วนโลหะให้ตรงตามแบบออกแบบอย่างแม่นยำ ไม่ว่ารูปร่างจะซับซ้อน หรือมีเส้นโค้งและมุมหลายจุดก็ตาม เครื่องอัดของ ZHONGYOU ติดตั้งระบบเซ็นเซอร์และระบบควบคุมอันทันสมัย ที่สามารถควบคุมแรงดันและความเร็วโดยอัตโนมัติ ซึ่งช่วยให้เครื่องทำงานได้ทั้งงานที่ต้องการความละเอียดแม่นยำและงานหยาบ โดยยังคงรักษาระดับความแม่นยำเท่าเดิม

เวลาการทำงานโดยทั่วไปมักใช้เวลานาน และต้องผ่านกระบวนการอัดหลายขั้นตอนในโครงการขึ้นรูปขนาดใหญ่ เครื่องอัดไฮดรอลิกสี่เสาจาก ZHONGYOU มีโครงสร้างที่แข็งแรง ทนทาน จึงสามารถทำงานต่อเนื่องได้อย่างสม่ำเสมอโดยไม่สูญเสียความแม่นยำ กรอบที่ทนทานช่วยให้เครื่องมีความมั่นคง ต้านทานการสึกหรอ ในขณะที่ระบบไฮดรอลิกให้พลังงานที่ลื่นไหลสำหรับทุกโครงการ สิ่งนี้ช่วยป้องกันการขัดข้อง และรักษาระยะเวลาการผลิตให้เป็นไปตามกำหนด

นอกจากนี้ เครื่องอัดไฮดรอลิกสี่เสาสามารถปรับขนาดได้ทั้งใหญ่ขึ้นหรือเล็กลงตามความต้องการของโครงการ รูปแบบและมิติของผลิตภัณฑ์แตกต่างกันไปในแต่ละอุตสาหกรรม ความหลากหลายนี้ทำให้เครื่องเหล่านี้เหมาะสำหรับการประยุกต์ใช้งานด้านการขึ้นรูปหลายประเภท เช่น ชิ้นส่วนยานยนต์ เครื่องใช้ไฟฟ้า และเครื่องจักรอุตสาหกรรม

สรุปแล้ว เครื่องอัดไฮดรอลิกสี่เสาจาก ZHONGYOU เหมาะอย่างยิ่งสำหรับการใช้งานที่ซับซ้อนและมีปริมาณสูง เนื่องจากมีความแข็งแรง ความแม่นยำ และความยืดหยุ่น เครื่องจักรเหล่านี้ถูกใช้ในการผลิตชิ้นส่วนโลหะคุณภาพสูงตามมาตรฐานที่เข้มงวด ช่วยให้มั่นใจได้ถึงความสำเร็จของโครงการทุกครั้ง

การผลิตด้วยความแม่นยำ การประยุกต์ใช้งานที่ดีที่สุดสำหรับเครื่องไฮดรอลิกสี่เสา

เครื่องอัดไฮดรอลิกแบบสี่เสาของ ZHONGYOU เป็นตัวเลือกที่ยอดเยี่ยมสำหรับการผลิตที่มีความแม่นยำ ช่วยให้สามารถขึ้นรูปชิ้นส่วนโลหะได้อย่างแม่นยำ อุตสาหกรรมยานยนต์ สถานที่ที่เครื่องอัดเหล่านี้ได้รับความนิยมมากที่สุดน่าจะเป็นในอุตสาหกรรมนี้ ชิ้นส่วนยานยนต์ เช่น แผงตัวถัง ชิ้นส่วนเครื่องยนต์ และชิ้นส่วนแชสซี จะต้องพอดีกันอย่างสมบูรณ์แบบและมีความแข็งแรงอย่างยิ่ง เครื่องอัดแบบสี่เสาของ ZHONGYOU จะให้แรงกดที่เหมาะสมและโครงสร้างที่มั่นคงเพื่อผลิตชิ้นส่วนเหล่านี้ได้อย่างถูกต้อง ซึ่งช่วยให้ผู้ผลิตรถยนต์สามารถผลิตยานยนต์ที่ปลอดภัยและเชื่อถือได้

อีกหนึ่งภาคอุตสาหกรรมที่สำคัญคืออุตสาหกรรมอิเล็กทรอนิกส์ ชิ้นส่วนโลหะขนาดเล็กเป็นสินค้าทั่วไปในอุปกรณ์อิเล็กทรอนิกส์ ซึ่งจำเป็นต้องขึ้นรูปอย่างแม่นยำ ความผิดพลาดเพียงเล็กน้อยอาจทำให้ชิ้นส่วนหักหรือไม่สามารถประกอบเข้าด้วยกันได้อย่างถูกต้อง เนื่องจากเครื่องอัดสี่เสาของ ZHONGYOU ควบคุมแรงดันและกระบวนการอัดขึ้นรูปได้อย่างมั่นคง จึงสามารถประมวลผลงานที่ละเอียดนี้ได้อย่างมีประสิทธิภาพ ส่งผลให้ชิป ขั้วต่อ และชิ้นส่วนอิเล็กทรอนิกส์อื่นๆ ทำงานได้อย่างไร้ที่ติ

เครื่องอัดไฮดรอลิกสี่เสาถูกใช้อย่างแพร่หลายในอุตสาหกรรมเฟอร์นิเจอร์และเครื่องใช้ไฟฟ้า สำหรับการผลิตชิ้นส่วนโลหะ เช่น กรอบ แผ่น และที่ยึด ซึ่งต้องมีรูปลักษณ์ที่ดี และมีความทนทานเพียงพอสำหรับการใช้งานประจำวัน เครื่องอัดของ ZHONGYOU ช่วยให้โรงงานสามารถผลิตชิ้นส่วนเหล่านี้ได้เร็วขึ้นและมีคุณภาพสูงด้วยความแม่นยำสูง ซึ่งหมายความว่าลูกค้าจะได้รับผลิตภัณฑ์ที่ทั้งทนทานและสวยงาม

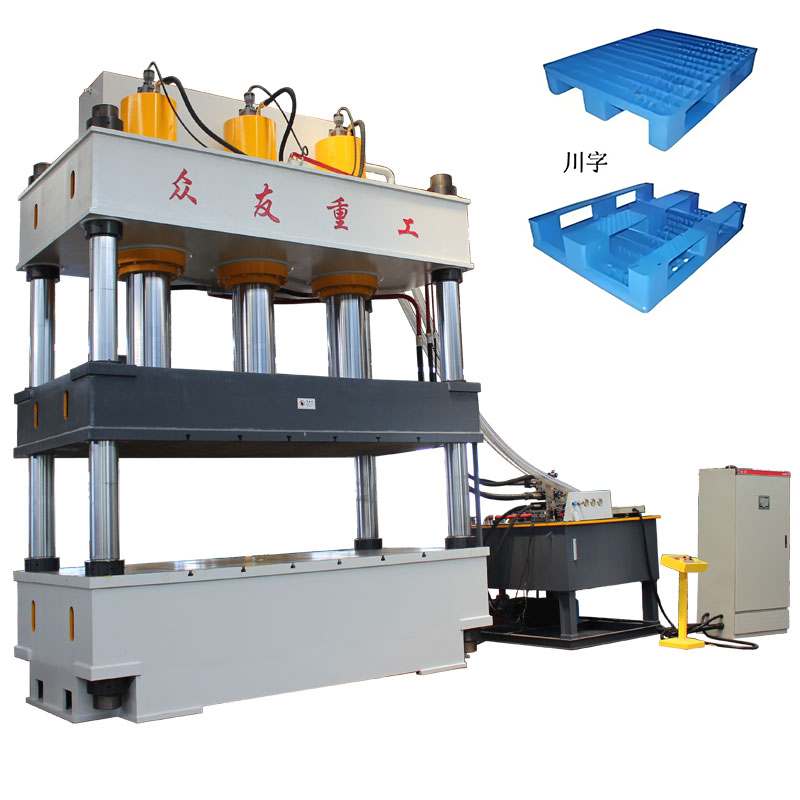

อีกหนึ่งสาขาที่ความแม่นยำมีความสำคัญอย่างยิ่ง คือ การผลิตอุปกรณ์ทางการแพทย์ เครื่องมือและอุปกรณ์ต่างๆ จำเป็นต้องสอดคล้องตามข้อกำหนดที่เข้มงวด เพื่อให้ถือว่าปลอดภัยและมีประสิทธิภาพ เครื่องอัดสี่เสาของ ZHONGYOU (ดังภาพด้านบน) ถูกใช้ในการขึ้นรูปชิ้นส่วนโลหะสำหรับเครื่องมือผ่าตัด เตียงโรงพยาบาล และอุปกรณ์การแพทย์อื่นๆ เครื่องจักรเหล่านี้มีความแม่นยำสูง เพื่อให้มั่นใจว่าชิ้นส่วนต่างๆ จะทำงานได้ดีและมีอายุการใช้งานยาวนาน

และในท้ายที่สุด การผลิตในอุตสาหกรรมการบินและอวกาศ มักเกี่ยวข้องกับการขึ้นรูปชิ้นส่วนโลหะขนาดใหญ่ตามกำหนดเวลาที่ค่อนข้างแน่นหนา เครื่องอัดสี่เสาของ ZHONGYOU เครื่องกดไฮดรอลิก มีความแข็งแรงและแม่นยำเพียงพอที่จะทำให้งานนี้ง่ายขึ้น ซึ่งเป็นสิ่งสำคัญสำหรับการสร้างชิ้นส่วนเครื่องบินที่ปลอดภัยและเบา

สรุป: เครื่องอัดไฮดรอลิกสี่เสาของ ZHONGYOU เป็นตัวเลือกที่ดีที่สุดในงานที่ต้องการความทนทานและความแม่นยำสูง การออกแบบที่แข็งแรงและการควบคุมอย่างแม่นยำทำให้เหมาะอย่างยิ่งสำหรับการขึ้นรูปชิ้นส่วนโลหะในหลากหลายอุตสาหกรรม และนี่คือวิธีที่ผู้ผลิตสามารถเข้าใจวิธีการผลิตสินค้าให้ดียิ่งขึ้นและปรับปรุงคุณภาพชีวิตของผู้คนทั่วโลก

สารบัญ

- เหตุใดเครื่องอัดไฮดรอลิกแบบสี่เสาจึงเหมาะสำหรับการประยุกต์ใช้งานด้านการขึ้นรูปที่ต้องการความแม่นยำ

- อะไรทำให้เครื่องอัดไฮดรอลิกสี่เสาเป็นสิ่งจำเป็นสำหรับการขึ้นรูปที่มีความแม่นยำและคุณภาพสูง?

- ปัญหาทั่วไปของเครื่องกดไฮดรอลิกแบบสี่เสาและแนวทางแก้ไขสำหรับชิ้นส่วนความแม่นยำ

- ข้อดีของเครื่องอัดไฮดรอลิกสี่เสาในโครงการขึ้นรูปที่ซับซ้อนและขนาดใหญ่

- การผลิตด้วยความแม่นยำ การประยุกต์ใช้งานที่ดีที่สุดสำหรับเครื่องไฮดรอลิกสี่เสา

EN

EN AR

AR BG

BG HR

HR FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID SK

SK SL

SL UK

UK VI

VI HU

HU MT

MT TH

TH TR

TR AF

AF GA

GA IS

IS AZ

AZ KA

KA BN

BN LA

LA MN

MN NE

NE KK

KK UZ

UZ KY

KY