|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ32-500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

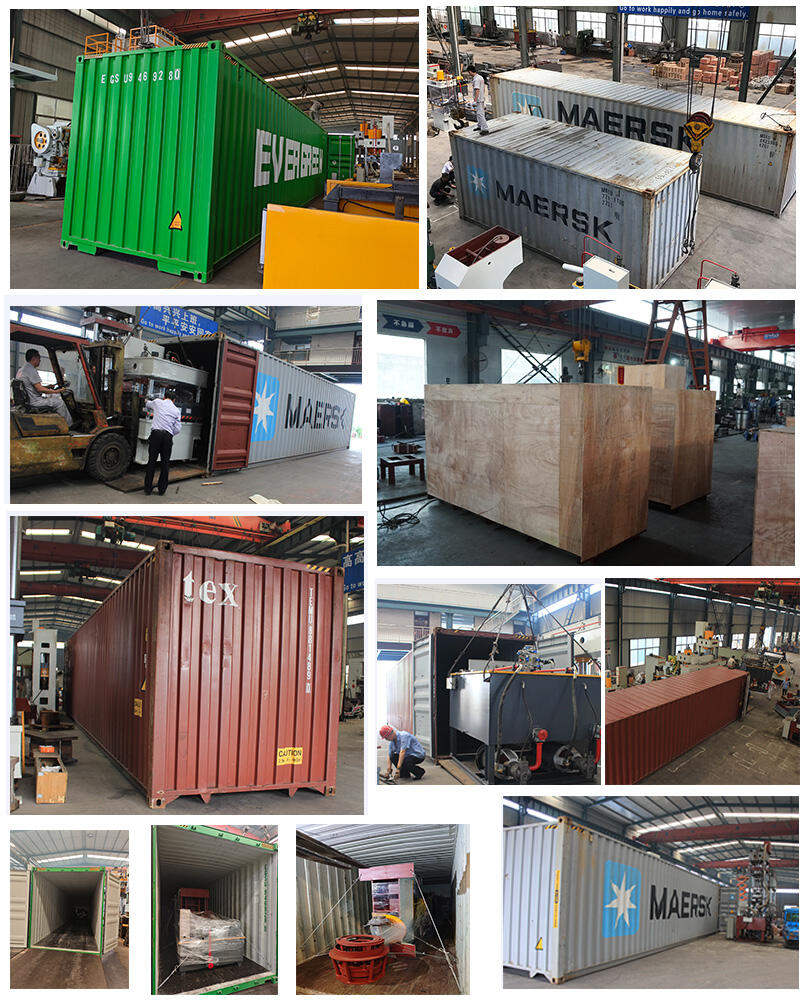

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

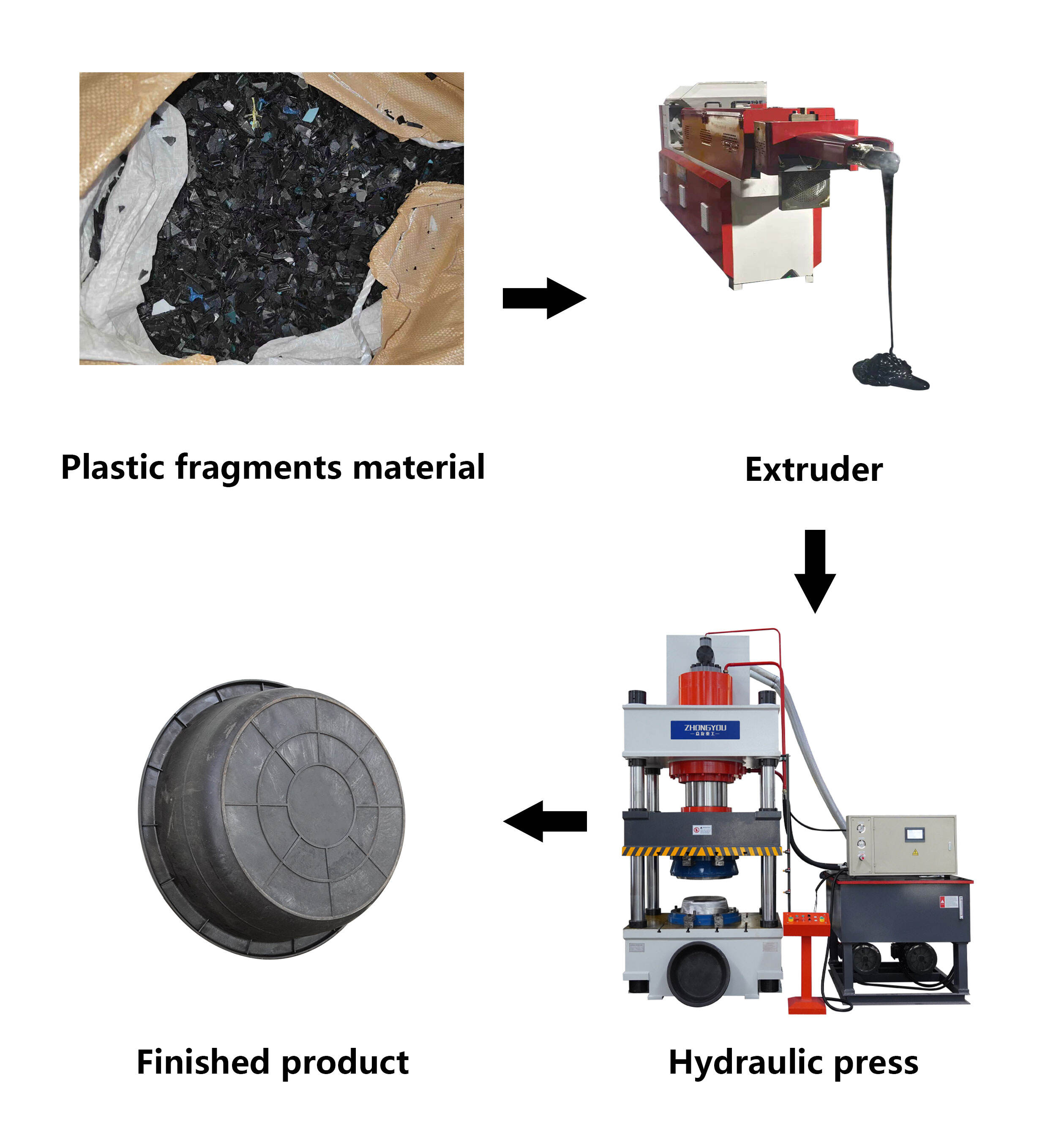

Plastic basin molding hydraulic press is specially used for large size plastic basin products (such as laundry basin, chemical liquid storage basin, agricultural water storage basin, etc.) molding special hydraulic equipment.

Plastic large basins are widely used in the following fields corresponding to the typical applications of hydraulic presses due to the advantages of chemical resistance, impact resistance, lightweight and easy to clean:

Household field: household laundry basin, car wash basin, kitchen storage basin (material is mostly PP/PE, need hydraulic press to support thermoplastic material molding).

Industrial field: chemical workshop acid and alkali liquid storage basin (made of fiberglass reinforced plastic or PVC, need to be temperature and corrosion resistance), electronic factory anti-static basin (made of conductive plastic).

Agricultural field: water storage basin in rural areas, feed basin for breeding (made of HDPE, large size and low cost).

Environmental protection: sewage treatment plant sewage storage basin (made of glass fiber reinforced polypropylene, high strength)

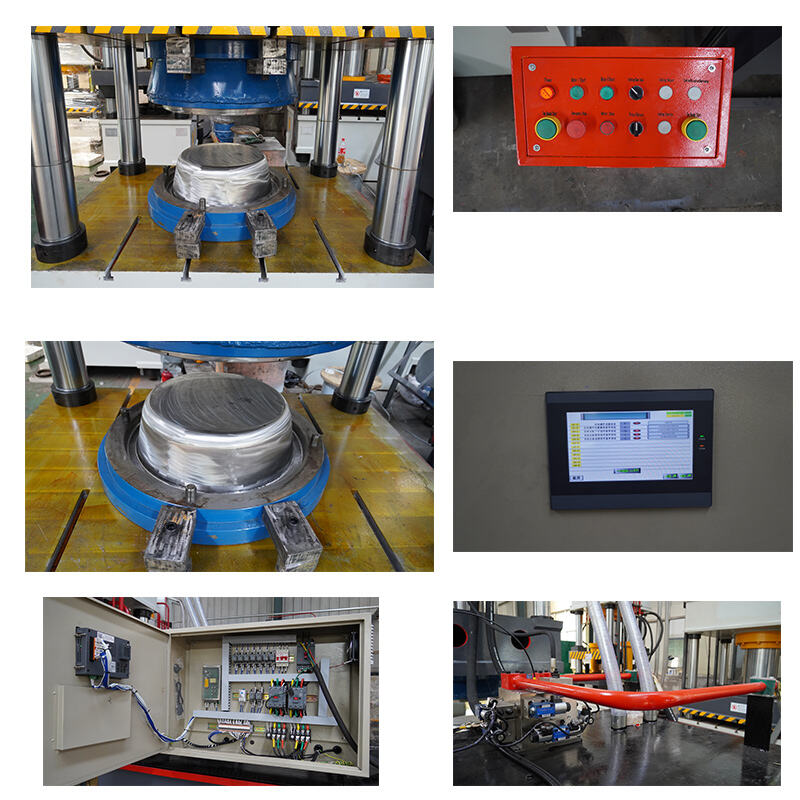

1. Large tonnage and large table: the travel of the movable beam needs to be large enough to ensure the space for mold installation and demolding.

2. Uniform pressure and temperature control: integrated heating and temperature control system, temperature control accuracy of ± 2 ℃, to meet the thermosetting material curing or thermoplastic material melting temperature Requirements

3. High rigidity and stability: the body is welded with thick steel plate + finite element analysis optimized structure.

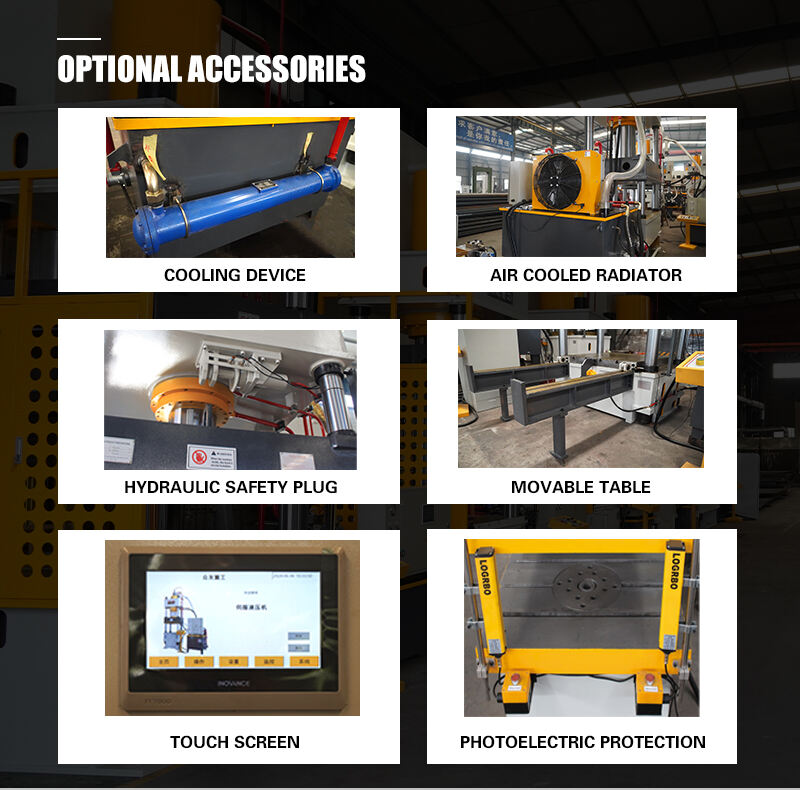

4. Automation and Intelligent: optional automatic feeding device (such as screw feeder, belt conveyor) and Robot picking up parts, reducing manual intervention and improving production efficiency.

5. Strong mold compatibility: support quick mold change (through positioning pin + locking device), to adapt to the production needs of different specifications of large pots (and reduce downtime for mold change.)

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved