|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

VTC65 |

|

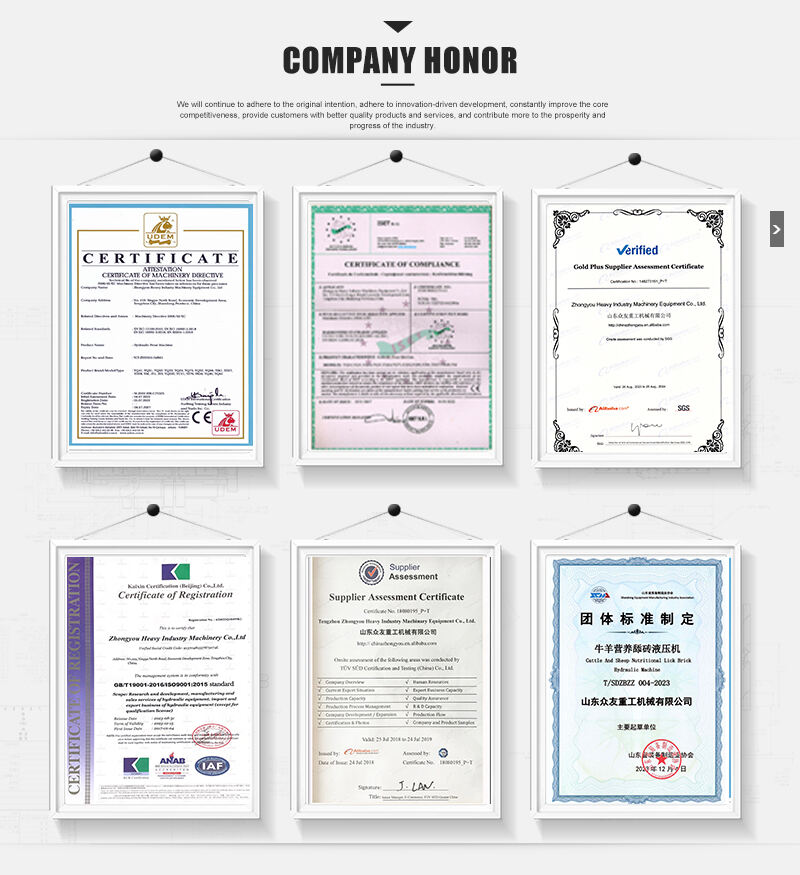

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

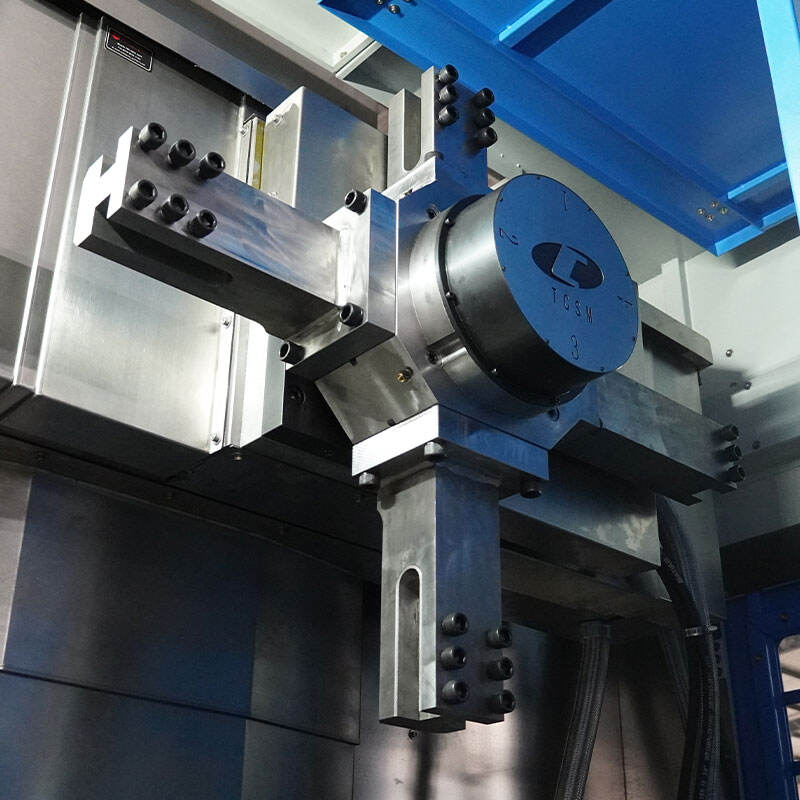

"VTC65 Vertical Lathe" usually refers to vertical lathes with a maximum machining diameter of 650mm (some manufacturers may vary slightly due to design differences), which belongs to small and medium-sized vertical lathes, CNC or general lathes. It belongs to small and medium-sized vertical lathe, CNC or general lathe, mainly used for processing large diameter, short and heavy disk, ring and flange parts.

| specifications | unit | VT45 | VT65 | VT75 | VTS525 | VTS527 |

| Max.rotating diameter | mm | ∮560 | ∮650 | ∮750 | ∮750 | ∮750 |

| Max.turning diameter of workpiece | mm | ∮450 | ∮600 | ∮700 | ∮550 | ∮700 |

| Spindle end face form | Straight | Straight | Straight | Straight | Straight | |

| Spindle speed | rpm | 3000 | 100-1000 | 50-1500 | 50-1000 | 500-1000 |

| Hydraulic chuck diameter | mm | 500 | 500 | 630 | 500 | 630 |

| Tool post type | pcs | eight-station | eight-station | eight-station | eight-station | eight-station |

| Tool shank diameter | mm | 32 | 32 | 32 | 32 | 32 |

| Inner diameter tool holder | mm | ∮40 | ∮40 | ∮50 | ∮50 | |

| Center tool holder | mm | 160 | ||||

| X axis travel | mm | 400 | 450 | 700 | 280 | 450 |

| Z axis travel | mm | 500 | 600 | 700 | 500 | 700 |

| Oil tank capacity | L | 50 | 50 | 50 | 50 | 50 |

| Oil pressure motor | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Water Capacity | L | 180 | 200 | 200 | 200 | 200 |

| Rotating water motor | w | 250 | 450 | 450 | 450 | 450 |

| Flush motor | kw | 250 | 450 | 450 | 450 | 450 |

| X axis servo motor torque | NM | 12 | 18 | 18 | 15 | 15 |

| Z axis servo motor torque | NM | 22 | 30 | 18 | 15 | 15 |

| Main Servo motor power | kw | 11/15 | 18.5 | 22 | 18.5 | 22 |

| Repeat positioning accuracy | mm | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 |

| Positioning accuracy | mm | ±0.008 | ±0.008 | ±0.008 | ±0.008 | ±0.008 |

| Dimension | mm | 1700X1880X2500 | 2000X1950X3000 | 2450X1900X3200 | 3000X2400X2700 | 3200X2400X3200 |

| Weight | kg | 5500 | 8000 | 9500 | 7000 | 9000 |

| Voltage | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | |

| Electricity Leakage/outage protection | √ | √ | √ | √ | √ | |

| Three-color light indication | √ | √ | √ | √ | √ | |

| Long-term stable working conditions | environment Temperature 5~38°, humidity <85% | environment Temperature 5~38°, humidity <85% | environment Temperature 5~38°, humidity <85% | environment Temperature 5~38°, humidity <85% | environment Temperature 5~38°, humidity <85% | |

| Noise meets national standards | √ | √ | √ | √ | √ | |

| ☆The equipment adopts fully enclosed protection, and the protective device is safe and reliable and should comply with GB15760-1995 General Technical Regulations on Safety Protection of Metal Cutting Machine Tools. ☆Equipped with various hydraulic, gas and water pipeline direction signs, marking the working range of various instruments, and marking the grade of the medium used. ☆The diameter of the hydraulic chuck and the tool holder station can be selected according to the processing requirements. |

||||||

Core Scenario:

Automotive parts: rough and finish machining of brake discs, wheel hubs, brake drums, flywheel housings, clutch housings and other disk parts.

Industrial field: aerospace (e.g. engine parts), rail transportation (e.g. wheel rims), construction machinery (e.g. slewing bearings), etc.

Machining capability:

It can complete the machining of internal and external cylindrical surfaces, taper surfaces, end face grooving, chamfering, threads and complex rotary surfaces (such as hyperbolic surfaces), and supports automatic tool change and multi-axis linkage.

High precision and stability:

Adopting precision spindle, linear rolling guide and ball screw, combined with fully enclosed protection design, conforming to GB15760-1995 safety standard, to ensure long-term accuracy maintenance.

Efficient automation:

High degree of automation, productivity is increased by more than 60% compared with traditional machine tools; support open loop/closed loop control, adapting to different processing needs.

Energy saving and environmental protection:

Adopting energy-saving motor and optimized design, energy consumption is reduced by 30%; equipped with separated cooling water tank, reducing pollution and extending tool life.

Customization ability:

Support the customization of chuck diameter, tool holder station, spindle speed and other parameters to adapt to special processing requirements (such as heavy disk gear turning).

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We provide a full set of hydraulic press equipment and CNC vertical lathe, with many mature design solutions and successful customer cases. We can also provide customized service, provide molding tooling and corresponding production line equipment, providing one-stop service for customers. Welcome to call us for consultation.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved