Have seen a big press machine that can apply a force as high as 400 tons? Behold this incredible machine, the 20 ton press! It is extremely strong and enables factories to transform metal into countless shapes and sizes. So this machine is semiphysical for the most industries that works with metal to fabricate their products.

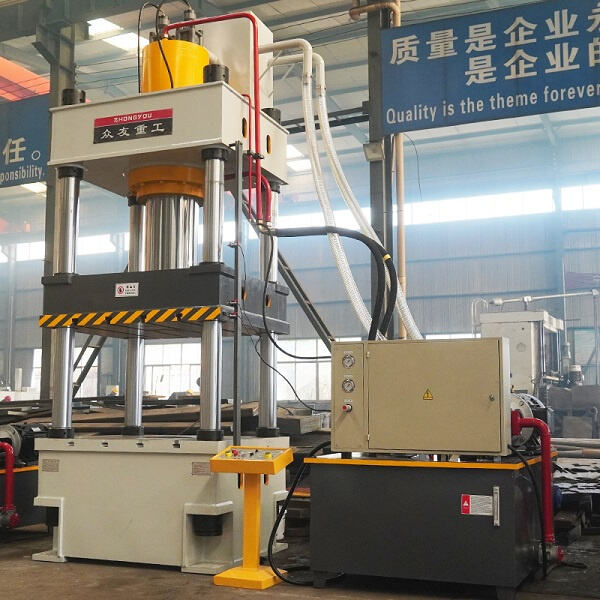

ZHONGYOU, specialized in manufacturing top quality 400 ton press. Such kinds are pretty essential and get utilized in a variety of ways for the betterment of the metal sector. We are proud to be able to provide our customers with these powerful machines that help them to develop the best products that they can.

Long ago, humans struck the metal with massive hammers to mold it. This was extremely time-consuming and labour intensive, though it could also be back-breaking work. But now, thanks to the incredible 20 ton hydraulic press, metal can be shaped in seconds simply by pushing a button. This significantly speeds things up and makes the whole process much easier!

The press is hydraulic, which is a special system. It does so by applying a great amount of force and then pressing the metal between two heavy plates. I mean, the pressure might even reach 400 tons! This means it can mould the metal without cracking or ruining its structure. Like super strength for shaping metal!

This powerful press allows every factory to produce many parts that are exactly the same size and shape. That’s especially crucial within the car industry, where each component has to click precisely into place. Even just one part being the wrong size will throw a spanner in the works when assembling the vehicle.”

The aerospace industry uses the press to form critical parts, like components for your airplane engine, but also other parts required for flight. In the automobile industry, it is used to produce the frames and other components necessary to manufacture cars. They use the press in construction to make steel beams and other strong materials for buildings and other structures. The process can be used to produce many items made out of metal and includes anything from tools to furniture.

The machine is also referred to as a stamping press and is used in manufacturing to transform metal into a variety of shapes and sizes. It is far quicker and yields superior results compared to manual processing. This press changes the game because it is more environmentally friendly, but can also be used in so many industries.

Founded in 2006, we are mostly involved in the development and production of hydraulic presses, with an experienced technical team committed to research and development as well as design. We are able to manufacture both small hydraulic presses and heavy hydraulic presses of 10,000 tonnes, fully meeting the needs of our clients. Our 40,000 square-meter facility is outfitted with the latest equipment, including high-end 400 ton press and CNC cutting machines.

Our products 400 ton press Four column press, H frame press C type press composite material press, powder forging press, custom-designed hydraulic press, etc. We are able to customize the equipment and supply the production line you need. We also can provide pressing tests to make sure that you can choose the most correct equipment.

Our hydraulic presses are CE certified by the EU as well as the ISO quality management systems. We have 400 ton press and honorary certificates. More than 50 countries, which includes Europe, America and Asia as well as Oceania and Africa are the home of our customers. Computer-optimized hydraulic presses have the most sensible and scientific design. The hydraulic system and electrical system use branded accessories to ensure high precision and durability of the machine.

We offer a comprehensive after-sales support including equipment installation commissioning operation training as well as other services We offer hydraulic press operating 400 ton press for users to understand how to operate and maintain hydraulic pressings Engineers will install and then test the equipment For transport we will secure the equipment and fix it by putting steel cables into the container to ensure the security of the equipment

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved