|

Place of Origin: |

Tengzhou China |

|

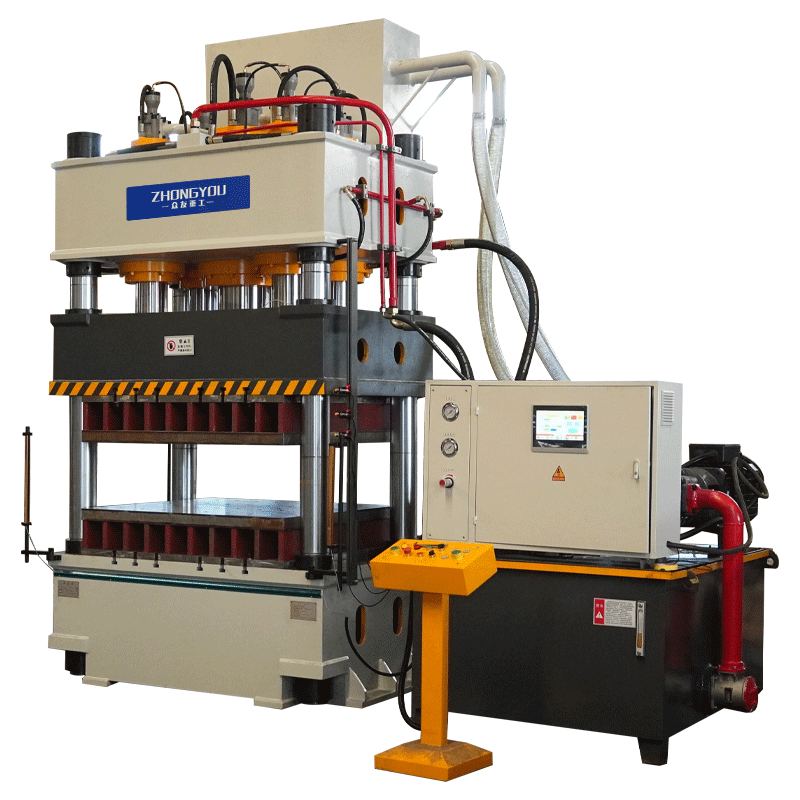

Brand Name: |

Zhongyou |

|

Model Number: |

YQ32-500T |

|

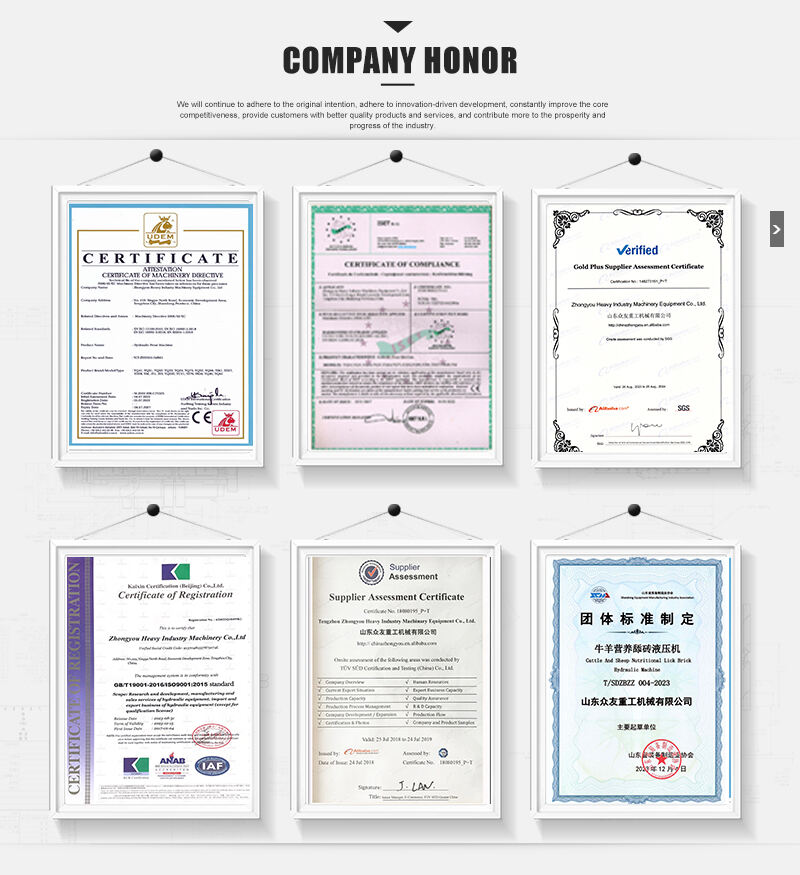

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

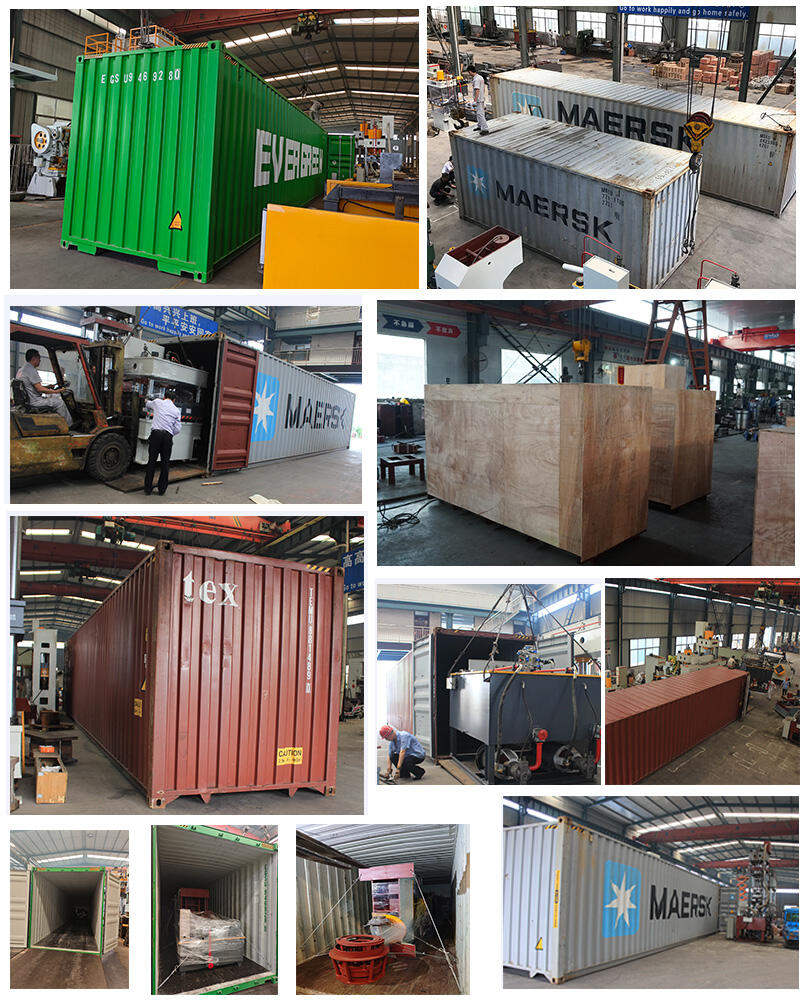

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

The combination of a 500-ton servo hydraulic press and a grating mold is widely used in precision machining scenarios in the automotive, aerospace, and electronics industries through high-precision control, safety and security, and energy-saving advantages. Selection should focus on the compatibility of the control system and the specific functional requirements of the grating.

|

YQ32 Technical Parameters |

||||||||

|

|

Unit |

YQ32—63 |

YQ32—100A |

YQ32—100B |

YQ32—200A |

YQ32—200B |

YQ32—315A |

YQ32—315B |

|

Nominal force |

KN |

630 |

1000 |

1000 |

2000 |

2000 |

3150 |

3150 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

700 |

800 |

900 |

900 |

1100 |

1000 |

1250 |

|

Max Stroke of Slider |

mm |

400 |

500 |

600 |

600 |

700 |

600 |

800 |

|

Effective table size |

mm |

610×500 |

630×550 |

750×700 |

800×800 |

1000×1000 |

800×800 |

1260×1160 |

|

Down speed |

mm/s |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Pressing speed |

mm/s |

11~22 |

7~15 |

7~15 |

7~18 |

7~18 |

7~12 |

7~12 |

|

Return speed |

mm/s |

80 |

90 |

90 |

90 |

90 |

90 |

100 |

|

Ejection cylinder force |

KN |

100 |

200 |

200 |

400 |

400 |

630 |

630 |

|

Stroke of ejection cylinder |

mm |

160 |

200 |

200 |

200 |

200 |

300 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

YQ32—400 |

YQ32—500 |

YQ32—630 |

YQ32—800 |

YQ32—1000 |

YQ32—1250 |

YQ32—1600 |

|

Nominal force |

KN |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

16000 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Max Stroke of Slider |

mm |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Effective table size |

mm |

1260×1160 |

1400×1400 |

1500×1500 |

1600×1600 |

1600×1600 |

1600×1600 |

1600×1600 |

|

Down speed |

mm/s |

100 |

150 |

150 |

180 |

180 |

180 |

190 |

|

Pressing speed |

mm/s |

5~11 |

10~18 |

9~18 |

9~18 |

10~18 |

6~15 |

6~14 |

|

Return speed |

mm/s |

100 |

180 |

200 |

180 |

220 |

200 |

220 |

|

Ejection cylinder force |

KN |

630 |

1000 |

1000 |

1000 |

1000 |

1000 |

1600 |

|

Stroke of ejection cylinder |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

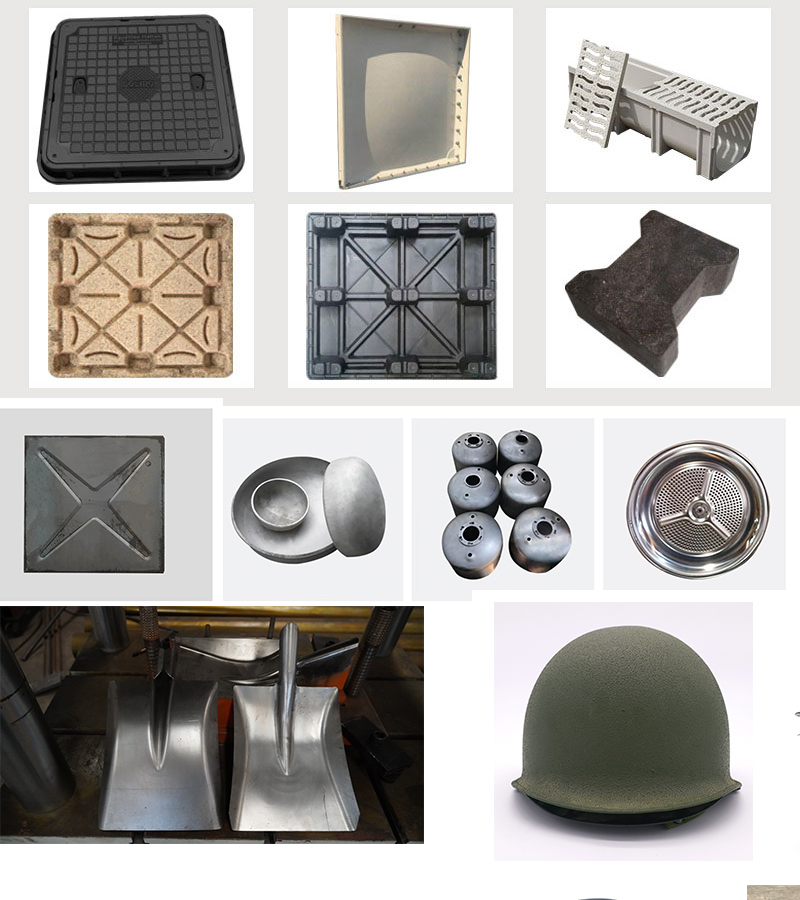

1. Precision electronic device molding

Mobile phone/notebook shell: precision stamping of aluminum alloy center frame, no scratches on the surface;

Connector terminal: cold heading molding of copper alloy connector, precision ±0.02mm, avoiding material breakage.

2. Automotive precision parts

Transmission gears: precision forging of 20CrMnTi gears with ISO 6 level of tooth precision;

Lightweight parts: hot die forging of aluminum alloy sub-frame, dimensional consistency, reducing the amount of subsequent machining.

3. Hard to deform material processing

Titanium alloy blade: precision die forging of TC4 titanium alloy blade for aero-engine,, avoiding folding defects;

Cemented carbide tool: blade press molding, density uniformity ± 0.5%, reduce sintering cracking.

4. Mold processing and repair

Mold research and matching: automotive cover part mold (such as the inner door panel) of the type surface gap detection, shorten the debugging cycle;

Mold repair: precision injection mold local patch welding after repair, grating mold monitoring type.

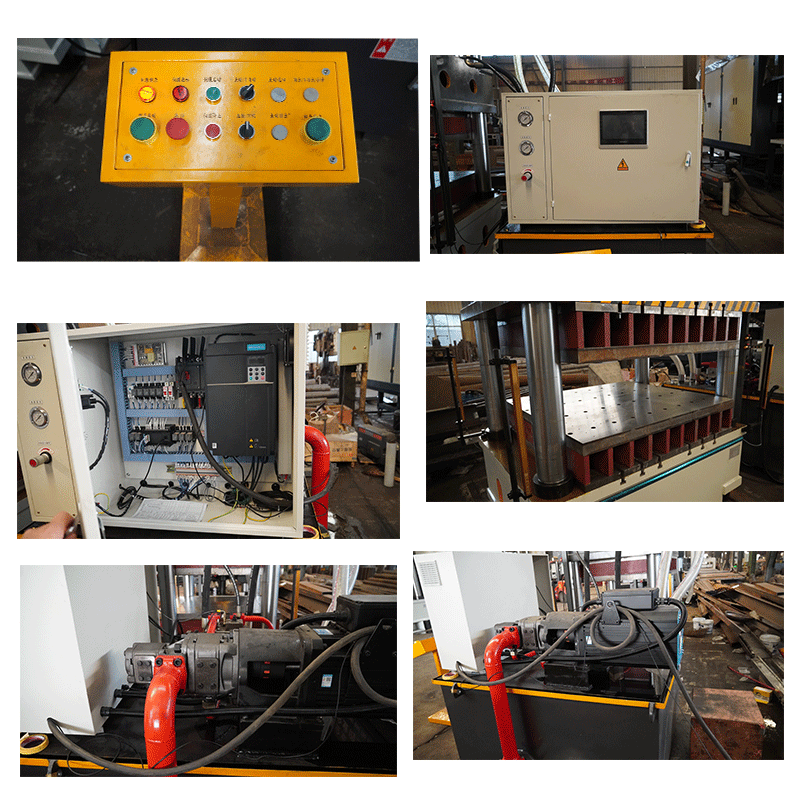

High Precision Processing

The scale provides real-time position feedback and the servo system dynamically adjusts the pressure and speed, which is suitable for high-precision molding of automotive interior parts (e.g., headliner, door panels), and the materials are suitable for PU boards, glass fiber reinforced plastics (GFRP), and so on.

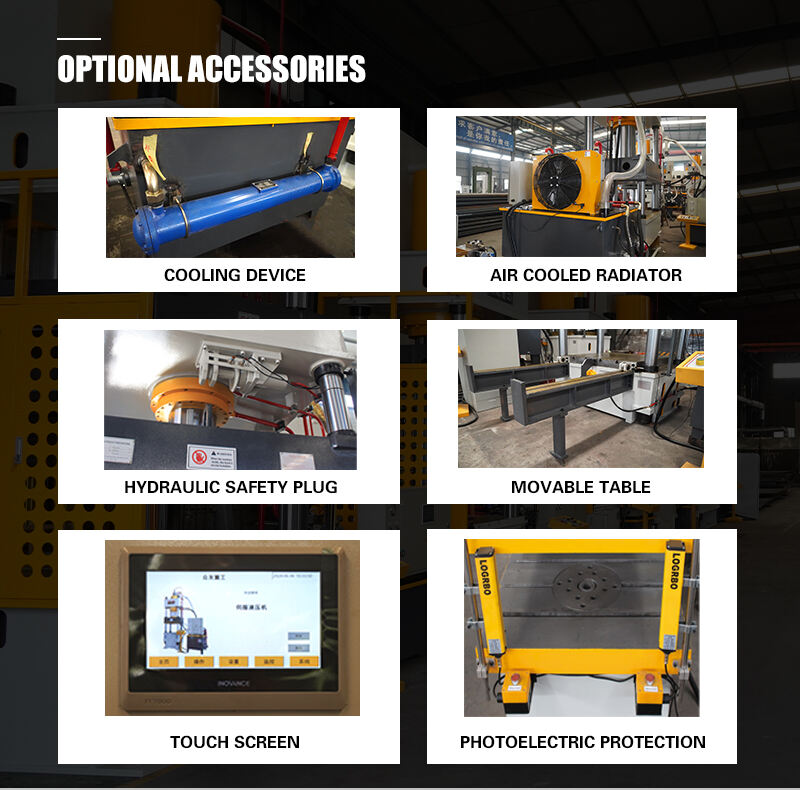

Safety and efficiency at the same time

Grating safety protection reduces downtime, and servo system raises the beat to 10-15 times/minute, increasing single-shift production capacity by 200%.

Application Scenario: In the automated production line, 500 tons servo hydraulic press + robot loading and unloading system + grating safety device, to achieve 24 hours continuous production.

Energy saving and environmental protection

Servo drive reduces energy consumption, no physical contact detection of the grating, reducing maintenance costs, in line with the trend of green manufacturing.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved