|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ32-500T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

500 tons double-cylinder hot press is a large tonnage, high-precision hydraulic molding equipment, mainly used for metal, non-metallic materials, precision compression molding process. It is a special hydraulic equipment designed for the molding and processing of automotive interior parts (such as instrument panels, door panels, carpets, roofs, acoustic cotton, etc.), which is mainly used for molding, hot press molding, polyurethane (PU) foam, composite material pressing and other processes. Its core features are high precision, high stability, and adaptability to multi-material process requirements.

500 tons double-cylinder hot press is widely used in the following fields because of its large tonnage, high precision and stable temperature control:

Powder metallurgy: pressing of iron-based, copper-based, cemented carbide and other powder products (such as gears, bearings, cutting tool blanks), which require pressure preservation and sintering integration.

Composite molding: carbon fiber reinforced plastic (CFRP), ceramic matrix composites (CMC) hot press curing (such as aerospace parts, wind turbine blades).

Metal precision forging: warm/hot die forging of stainless steel, titanium alloys and other hard-to-deform materials (e.g., aero-engine turbine disk preforms).

New energy field: hot pressing of lithium battery pole pieces (to improve density and consistency), molding of bipolar plates for fuel cells.

Non-metallic materials: high-temperature and high-pressure molding of rubber products (e.g., tire treads) and plastic sheets (e.g., PEEK, PI).

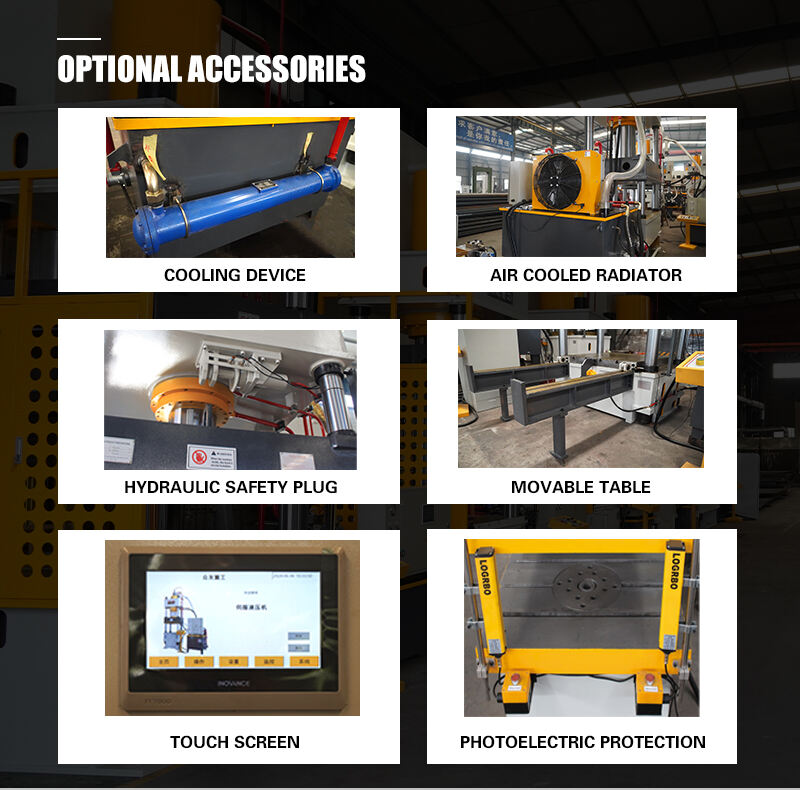

Four-column and frame type dual mainstream design

Four-column type: adopting three-beam and four-column structure, optimizing the rigidity of the machine body through finite element analysis to ensure even pressure bearing on the large table surface.

Frame type: the whole steel plate is welded to eliminate stress, and the slider adopts multi-face guide rail design, which improves the stamping precision by more than 30%.

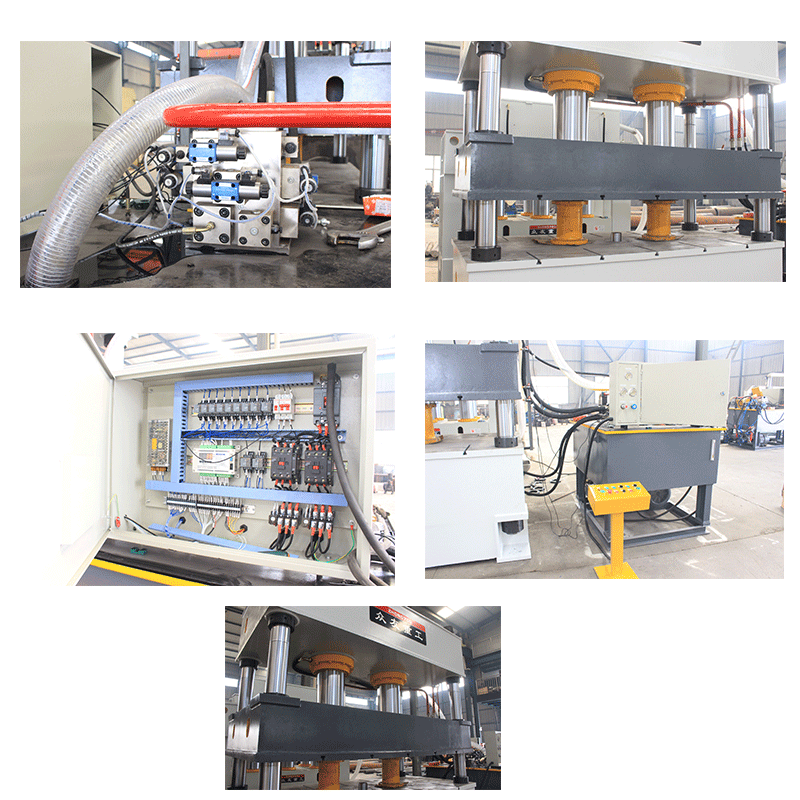

Hydraulic system and control technology

Integrated cartridge valve: Realize 40% increase in action sensitivity and leakage-free operation.

Safety and energy-saving design

Hydraulic safety circuit: Equipped with a dead center locking mechanism on the slide to prevent accidental falling.

Energy recovery system: some models are driven by servo motors, reducing energy consumption by 30% and meeting the demand for low-carbon production in the automotive industry.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved