|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ32-250T |

|

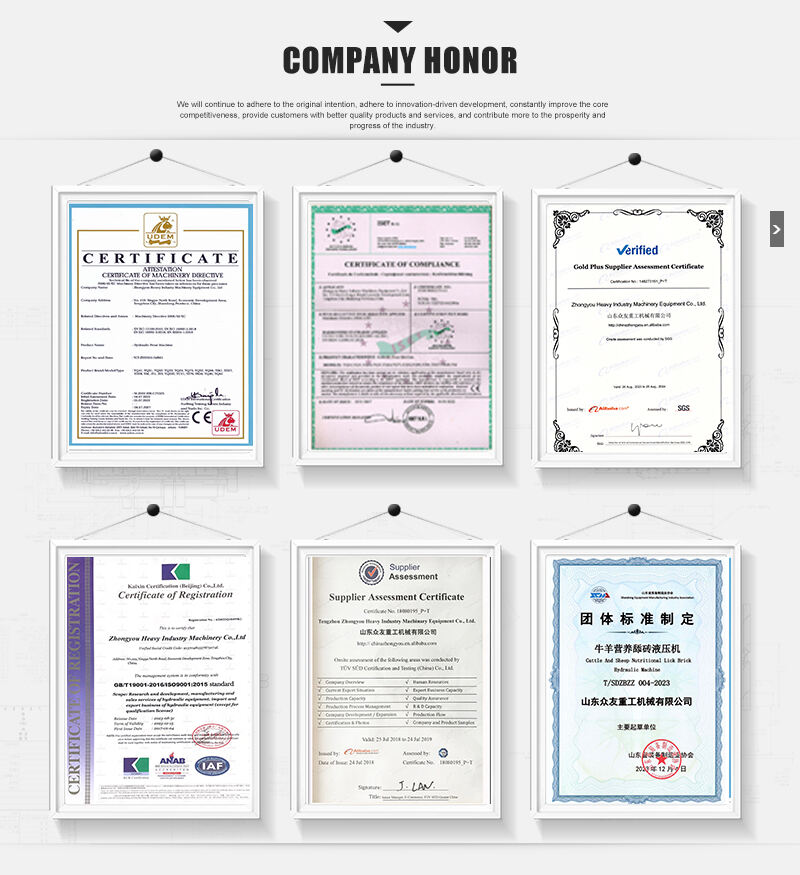

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

This250T Up Stroke Composite Hot Press Machine is used for pressing carbon fiber automotive parts. It is designed with a under-roof structure and a nominal pressure of 250 tons, which is widely used in the fields of metal forming, powder metallurgy and composite material pressing.

|

YQ32 Technical Parameters |

||||||||

|

|

Unit |

YQ32—63 |

YQ32—100A |

YQ32—100B |

YQ32—200A |

YQ32—200B |

YQ32—315A |

YQ32—315B |

|

Nominal force |

KN |

630 |

1000 |

1000 |

2000 |

2000 |

3150 |

3150 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

700 |

800 |

900 |

900 |

1100 |

1000 |

1250 |

|

Max Stroke of Slider |

mm |

400 |

500 |

600 |

600 |

700 |

600 |

800 |

|

Effective table size |

mm |

610×500 |

630×550 |

750×700 |

800×800 |

1000×1000 |

800×800 |

1260×1160 |

|

Down speed |

mm/s |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Pressing speed |

mm/s |

11~22 |

7~15 |

7~15 |

7~18 |

7~18 |

7~12 |

7~12 |

|

Return speed |

mm/s |

80 |

90 |

90 |

90 |

90 |

90 |

100 |

|

Ejection cylinder force |

KN |

100 |

200 |

200 |

400 |

400 |

630 |

630 |

|

Stroke of ejection cylinder |

mm |

160 |

200 |

200 |

200 |

200 |

300 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

YQ32—400 |

YQ32—500 |

YQ32—630 |

YQ32—800 |

YQ32—1000 |

YQ32—1250 |

YQ32—1600 |

|

Nominal force |

KN |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

16000 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Max Stroke of Slider |

mm |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Effective table size |

mm |

1260×1160 |

1400×1400 |

1500×1500 |

1600×1600 |

1600×1600 |

1600×1600 |

1600×1600 |

|

Down speed |

mm/s |

100 |

150 |

150 |

180 |

180 |

180 |

190 |

|

Pressing speed |

mm/s |

5~11 |

10~18 |

9~18 |

9~18 |

10~18 |

6~15 |

6~14 |

|

Return speed |

mm/s |

100 |

180 |

200 |

180 |

220 |

200 |

220 |

|

Ejection cylinder force |

KN |

630 |

1000 |

1000 |

1000 |

1000 |

1000 |

1600 |

|

Stroke of ejection cylinder |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

It can be used for hot molding of composite materials such as FRP, resin, carbon fiber and Kevlar.For example, automotive lightweight manufacturing

Carbon fiber parts reduce weight by more than 50% compared to traditional metal parts, significantly improving fuel economy and electric vehicle range.For example, carbon fiber wheels can reduce unsprung mass and improve handling performance.

Complex Structural Molding

Hydraulic presses can mold complex curved surfaces or shaped structures in a single pass, reducing the need for subsequent machining processes.

It is suitable for high-end automobile brands or racing cars, and meets the demand for customized and small-lot production.

High Precision Molding Capability

Stable pressure (usually up to hundreds to thousands of tons) is provided by the hydraulic system, combined with a precise temperature control system (electric, oil or steam heating) to ensure that the composite materials are uniformly cured at high temperature and high pressure to meet the stringent requirements of strength, rigidity, and light weight of the products.

It is suitable for the molding of carbon fiber wheel hubs, hoods, tail wings, interior parts, and various plastic products, composite products and other complex structural parts.

Intelligent control system

Equipped with PLC or servo system, it can monitor and adjust the parameters of pressure, temperature and time in real time to ensure the consistency and stability of the molding process.

It supports multi-stage pressure and temperature curve programming, adapting to the process requirements of different composite materials.

High efficiency and energy saving design

Adopting servo hydraulic system, compared with the traditional hydraulic press, energy saving more than 30%, while reducing noise and oil temperature fluctuation.

Fast mold closing/opening function (e.g. mold closing speed up to 200mm/s for 200 tons model), to improve production efficiency.

Safety and Reliability

Equipped with hydraulic safety valve, overload protection device and emergency stop button to ensure safe operation.

Key components (e.g. hydraulic cylinders, seals) are made of high wear-resistant materials to prolong equipment life.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved