|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ32-250T |

|

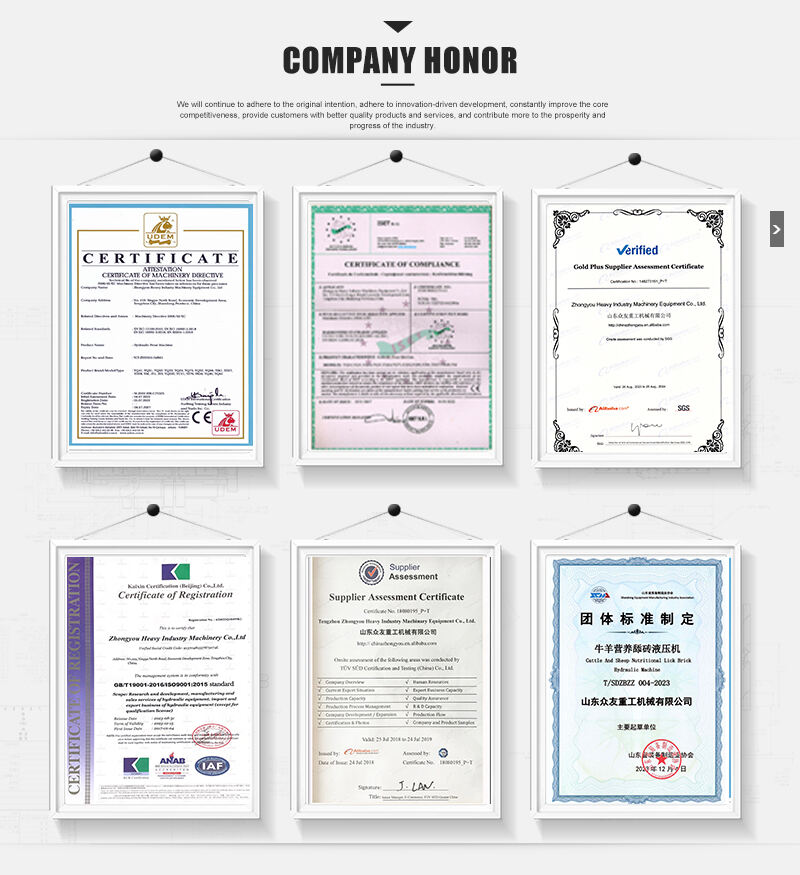

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

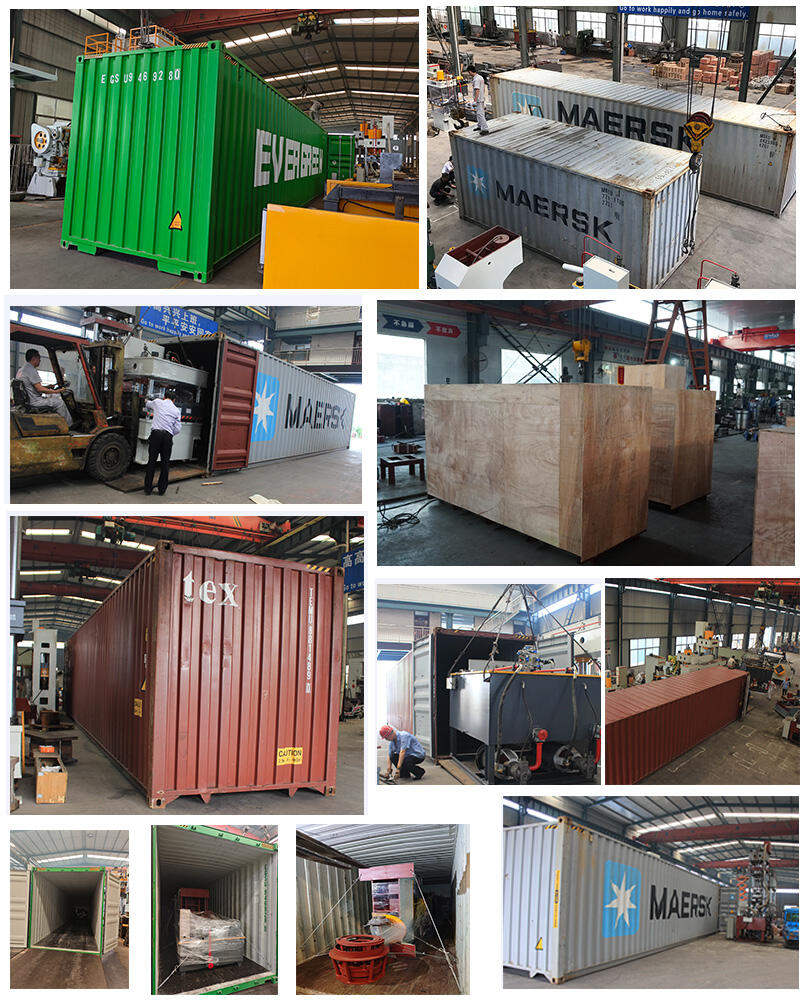

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

250 tons servo with industrial refrigeration hydraulic press is a combination of servo drive technologyand industrial refrigeration system of medium-sized hydraulic molding equipment, mainly used for metal plate stamping, stretching, bending, precision pressing and other processes.Its core feature is "high precision control by servo drive" and "stable oil temperature guarantee by industrial refrigeration", which is suitable for the scenes with high requirements on molding quality, energy consumption and efficiency.

|

YQ32 Technical Parameters |

||||||||

|

|

Unit |

YQ32—63 |

YQ32—100A |

YQ32—100B |

YQ32—200A |

YQ32—200B |

YQ32—315A |

YQ32—315B |

|

Nominal force |

KN |

630 |

1000 |

1000 |

2000 |

2000 |

3150 |

3150 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

700 |

800 |

900 |

900 |

1100 |

1000 |

1250 |

|

Max Stroke of Slider |

mm |

400 |

500 |

600 |

600 |

700 |

600 |

800 |

|

Effective table size |

mm |

610×500 |

630×550 |

750×700 |

800×800 |

1000×1000 |

800×800 |

1260×1160 |

|

Down speed |

mm/s |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Pressing speed |

mm/s |

11~22 |

7~15 |

7~15 |

7~18 |

7~18 |

7~12 |

7~12 |

|

Return speed |

mm/s |

80 |

90 |

90 |

90 |

90 |

90 |

100 |

|

Ejection cylinder force |

KN |

100 |

200 |

200 |

400 |

400 |

630 |

630 |

|

Stroke of ejection cylinder |

mm |

160 |

200 |

200 |

200 |

200 |

300 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

YQ32—400 |

YQ32—500 |

YQ32—630 |

YQ32—800 |

YQ32—1000 |

YQ32—1250 |

YQ32—1600 |

|

Nominal force |

KN |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

16000 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Max Stroke of Slider |

mm |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Effective table size |

mm |

1260×1160 |

1400×1400 |

1500×1500 |

1600×1600 |

1600×1600 |

1600×1600 |

1600×1600 |

|

Down speed |

mm/s |

100 |

150 |

150 |

180 |

180 |

180 |

190 |

|

Pressing speed |

mm/s |

5~11 |

10~18 |

9~18 |

9~18 |

10~18 |

6~15 |

6~14 |

|

Return speed |

mm/s |

100 |

180 |

200 |

180 |

220 |

200 |

220 |

|

Ejection cylinder force |

KN |

630 |

1000 |

1000 |

1000 |

1000 |

1000 |

1600 |

|

Stroke of ejection cylinder |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

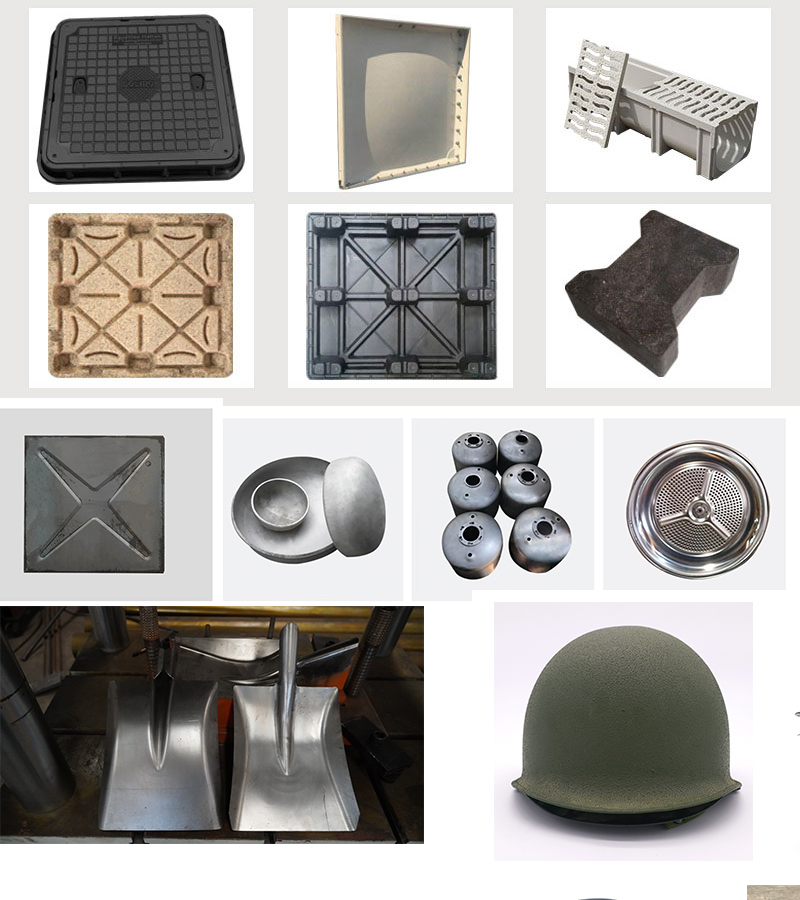

1.Automobile parts

Precision stamping: door latches, seat belt reels, hood lock tabs;

Connection terminal molding: automotive wiring harness terminals

New energy battery parts: battery pole lug bending, battery box flange forming (aluminum alloy, need to avoid surface scratches).

2. 3C electronics and home appliances

Mobile phone/tablet middle frame: precision stretching of aluminum alloy/stainless steel middle frame;

Home appliance shell: air conditioner heat sink (aluminum foil, need to control the stretching depth and wall thickness uniformity);

Connectors: cell phone SIM card tray, Type-C interface (copper alloy, high dimensional accuracy ±0.05mm required).

3. Hardware and tools

Precision knives: art knife blades (SKD11 mold steel, need to control edge sharpness);

Hardware: Door handles, locks (cold rolled steel, no surface indentation).

4. New energy and aviation

New energy: photovoltaic support (galvanized steel, need to control the bending angle ± 0.5 °);

Aviation: aluminum alloy structural parts (such as aircraft skin reinforcement, high consistency).

Servo motor drive system

Adopting servo motor to directly drive the main drive oil pump, eliminating the proportional servo valve or proportional pump link of the traditional hydraulic press, the system response speed is increased by more than 50%.

Remarkable energy saving effect: according to the processing technology and production beat different, compared with the traditional hydraulic press can save 30% -70% of electricity.

Low-noise operation: internal gear pumps or high-performance vane pumps instead of axial piston pumps, the noise is reduced by 5-10dB; the motor speed is 0 when the slider is stationary, and the noise emission is basically zero, which meets the ISO 11699 standard (≤70dB).

Quick cylinder and cartridge valve integrated control, the hydraulic cylinder provides 250 tons nominal pressure, quick cylinder to achieve the slider fast descent and return, the speed up to 200mm / s

Cartridge valve system: pressure and stroke can be adjusted steplessly, supporting both fixed-pressure and fixed-range processes, shortening the commutation time to less than 0.2 seconds, reducing non-production time by 30%.

Closed-loop control: real-time monitoring of the slider position and pressure through displacement sensors and pressure sensors, deviation correction time ≤ 0.1 seconds, to ensure product repetitive positioning accuracy ± 0.05mm.

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved