|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

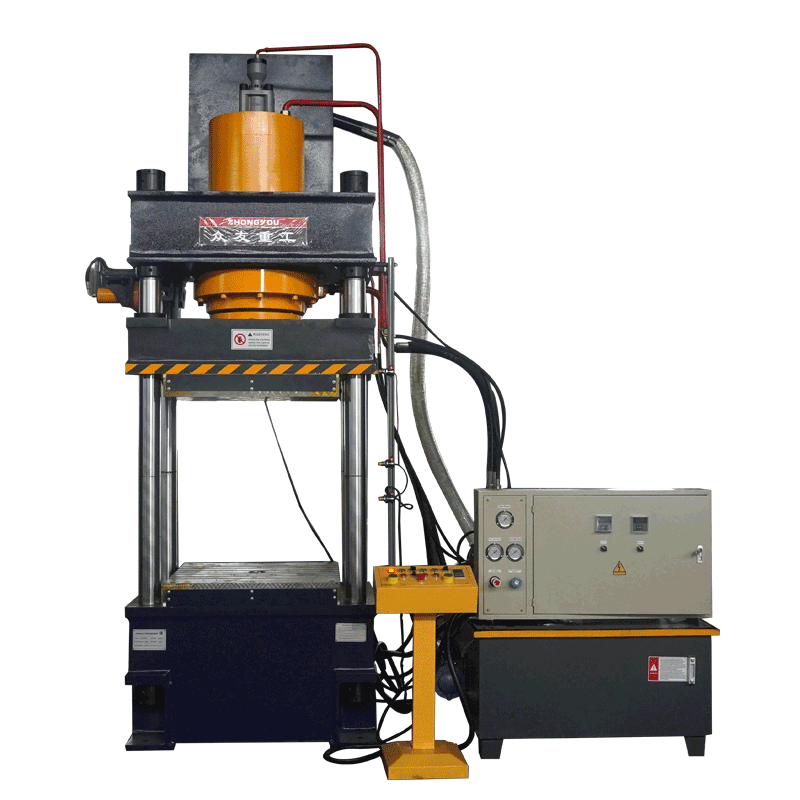

Zhongyou |

|

Model Number: |

YQ32-200T |

|

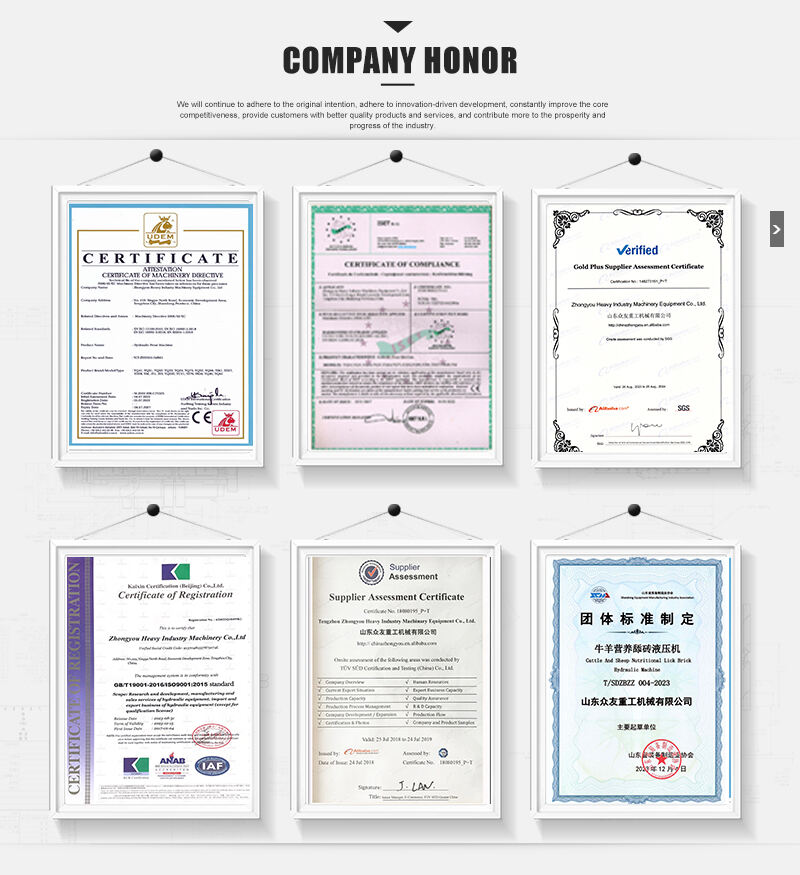

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

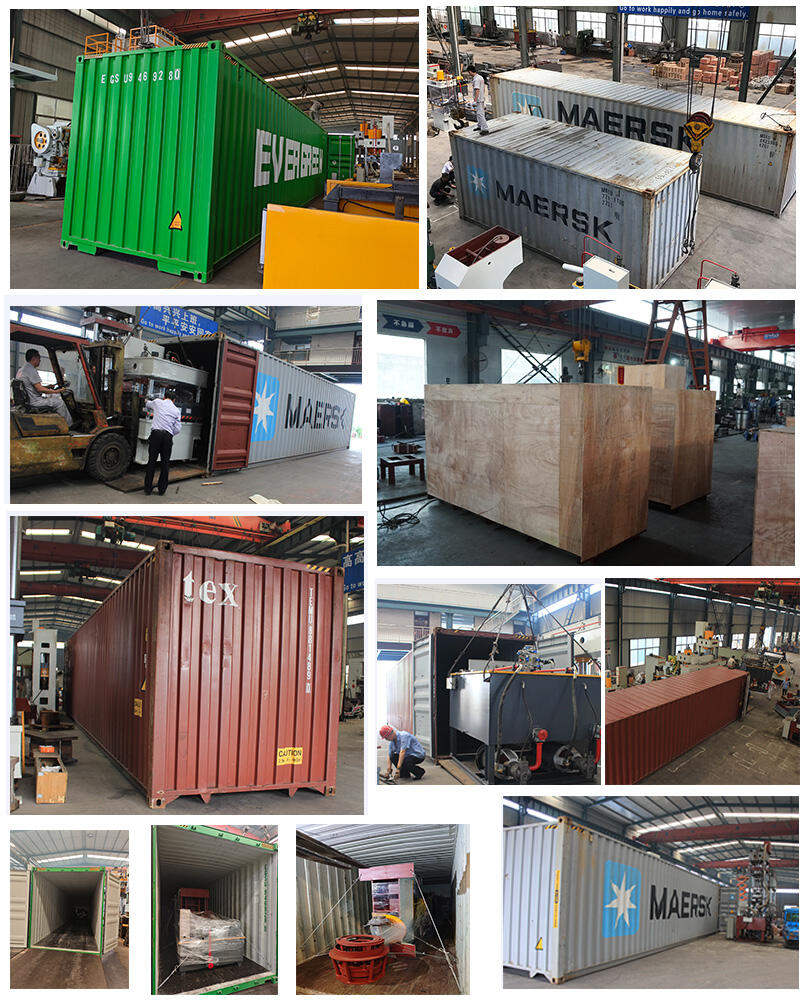

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

200 tons three-beam four-column hot press is a medium and large-scale hot press molding equipment, the core through the "hydraulic pressure + heating" to achieve the material (such as wood, plastic, composite materials.),Rubber, etc.) molding or curing reaction, widely used in building materials, furniture, industrial molds, new materials and other fields.

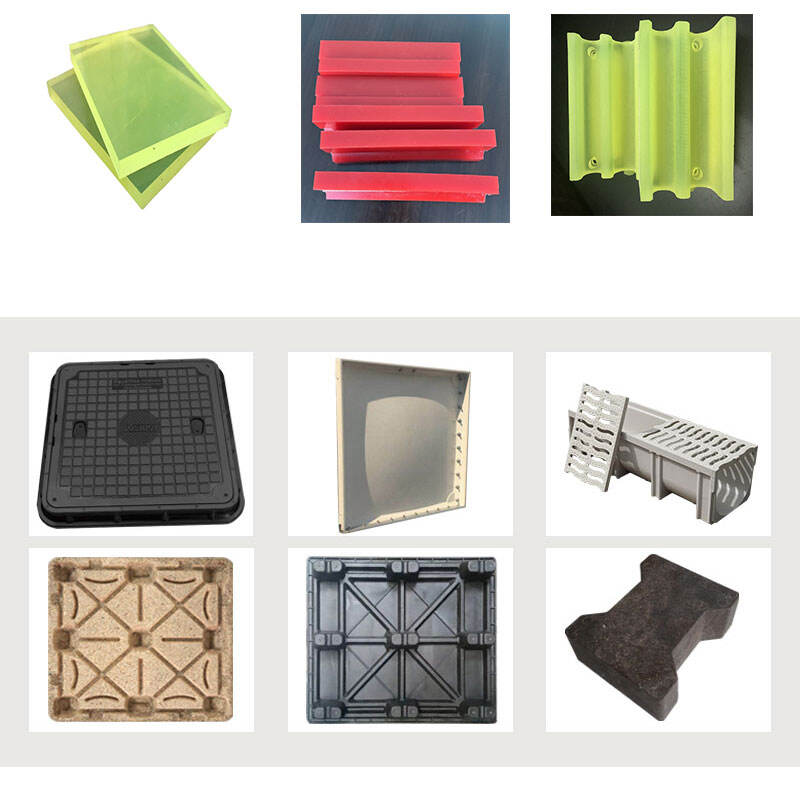

Wood processing and building materials

Products: plywood, density board, reconstituted bamboo flooring, construction templates;

2. Plastic and Rubber Products

Products: thermosetting plastics (e.g. phenolic plastics, epoxy resins) molded parts (gears, insulating parts), rubber seals (O-rings, shock absorbing pads);

3. Composite material molding

Products: fiberglass reinforced plastic (FRP) products (boat parts, wind turbine blades), carbon fiber prepreg molded parts (automotive structural parts);

4. New Material R&D

Products: high-performance ceramic blanks, nanocomposites (e.g. graphene reinforced plastics);

High rigidity frame design

Adopting integral casting or profile steel welding frame structure, the machine body is highly rigid, and the resistance to partial load is significantly better than the ordinary three-beam and four-column structure.For example, Wuxi Pengda Hydratron's composite material hydraulic presses, designed to pass European standards, maintain stable operation of ABS in continuous coin tests, ensuring no deformation in long-term use.

Optimization of four-column guiding precision

The four-column structure is designed through computer optimization, and the guiding accuracy can reach 0.02-0.03mm, which, together with the guide rail automatic lubrication device, effectively reduces the wear of the guide column and extends the life of the equipment."

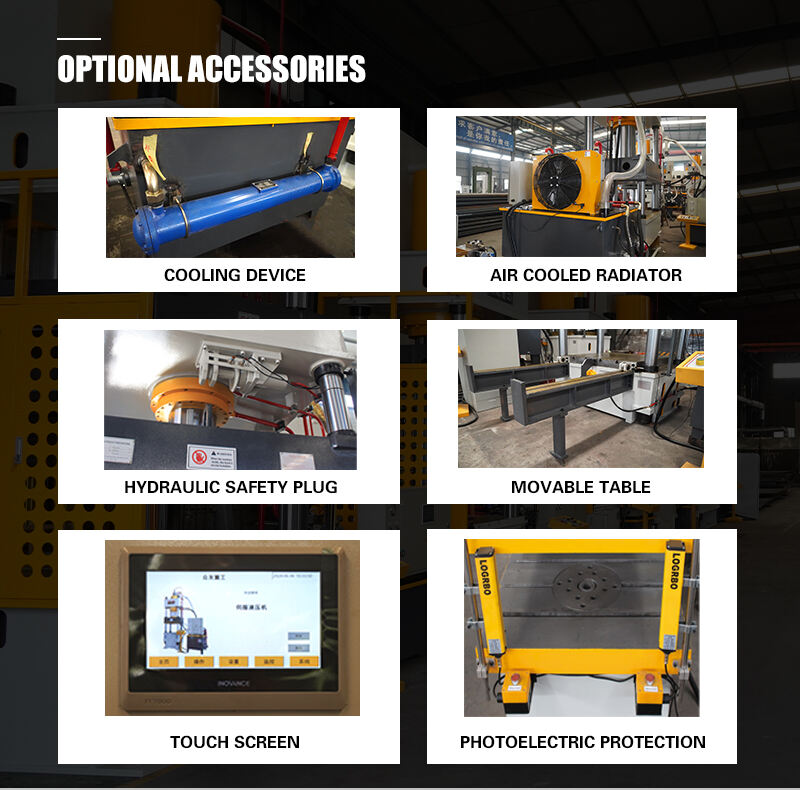

We offer comprehensive after-sales services, including installation, commissioning, and operation training; providing hydraulic press user manuals to facilitate user learning on how to operate and maintain the hydraulic press.

We offer a full range of hydraulic press equipment, with numerous mature design solutions and successful customer cases. Custom services are also available, providing forming molds and corresponding production line equipment, offering one-stop service. Welcome to consult with us.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved